JasonPAtkins

Hot Rolled

- Joined

- Sep 30, 2010

- Location

- Guinea-Bissau, West Africa

Hey all - I'm trying to get a lathe that's been sitting for a long time going. I have two lathes in my shop, and I have a good number of hours under my belt doing repair type jobs on my 15x48 Colchester that came to me with no half nut, just using taps and dies when threading is required.

So, I'm not a lathe noob, but am to single point threading. I'm trying to learn (because I ran into a job for which I don't have a die, haha) to single point on my smaller Portuguese Adira lathe. However, I'm either misunderstanding something or it's not set up for it??

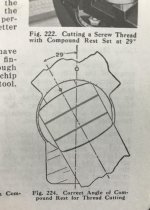

I made a screw (pic below) and as you can see, the thread is asymmetrical. (The insert is a standard 60 degree thread cutting insert which I squared to the chuck using a proper fishtail, I don't think any of that is suspect.) Obviously (I think) I had the compound at 30 instead of 60 or vice versa depending on how you read it. The compound graduation reads zero when the compound is moving parallel to the ways, perpendicular to the axis of spindle rotation. I cut the pictured thread with that at 30, which I'm pretty sure is wrong, as it should be 30 (29.5) from the spindle rotation axis, not 30 degrees from the saddle movement, correct? So the results I got aren't surprising given the mistake.

However, I made the mistake because of something that is surprising: the compound angle graduations stop at 45! I think I need to set to 60.5 degrees if zero is compound movement parallel to the ways, right? Well it's not graduated that far. I have to be overlooking something simple, because what lathe is made not to be able to thread, and then shipped with change gears and a chart to do exactly that? This isn't a chinese tray top. It's no beast, but it's a real lathe. I also thought maybe there was a zero mark on the handwheel side of the compound, 90 degrees from the mark in the pics, so that maybe you'd line that one up on the graduation marks at 30. But there isn't, and that would be really hard to see even if there was.

I think I can get around the problem with an angle gauge against the chuck, but doesn't this seem strange, or am I totally missing something?

So, I'm not a lathe noob, but am to single point threading. I'm trying to learn (because I ran into a job for which I don't have a die, haha) to single point on my smaller Portuguese Adira lathe. However, I'm either misunderstanding something or it's not set up for it??

I made a screw (pic below) and as you can see, the thread is asymmetrical. (The insert is a standard 60 degree thread cutting insert which I squared to the chuck using a proper fishtail, I don't think any of that is suspect.) Obviously (I think) I had the compound at 30 instead of 60 or vice versa depending on how you read it. The compound graduation reads zero when the compound is moving parallel to the ways, perpendicular to the axis of spindle rotation. I cut the pictured thread with that at 30, which I'm pretty sure is wrong, as it should be 30 (29.5) from the spindle rotation axis, not 30 degrees from the saddle movement, correct? So the results I got aren't surprising given the mistake.

However, I made the mistake because of something that is surprising: the compound angle graduations stop at 45! I think I need to set to 60.5 degrees if zero is compound movement parallel to the ways, right? Well it's not graduated that far. I have to be overlooking something simple, because what lathe is made not to be able to thread, and then shipped with change gears and a chart to do exactly that? This isn't a chinese tray top. It's no beast, but it's a real lathe. I also thought maybe there was a zero mark on the handwheel side of the compound, 90 degrees from the mark in the pics, so that maybe you'd line that one up on the graduation marks at 30. But there isn't, and that would be really hard to see even if there was.

I think I can get around the problem with an angle gauge against the chuck, but doesn't this seem strange, or am I totally missing something?