Your bravery Sir, is only exceeded by your ambition!

In the 70's, my wife and I traveled some, (as much as we could) of the Alpine region, particularly Austria and Switzerland. In one of the first very steep little dairy farms that we visited in Austria, we were charmed by the husband and wife team and their Pasquali tractor. They had a good array of the many implements, the hay mower working that day.

I was in awe of the steep terrain that the little ultra-low C.G tractor could negotiate without rolling over. On that day, he was cutting hay in the dozens of little, I have to call them pens, not big enough to warrent the designation "small pasture". Perhaps 35-40 meters square. All linked with gates.

She was following and pitching the mown hay onto the fences. Off season the cattle were let into the closest pen and when they'd consumed all the hay on those fences, the next pen would be opened. In spite of snow, the hay was easily aquired by the cattle, high on the fence. I don't know but I imagine that they covered the "fenced" hay after drying.

We were also charmed to discover that Tyrolian dress was alive and well in the Alps, he in Lederhosen and she in that charming style of dress, including flowers. Unfortunately, false alarm, they were the only farmers we found in other than modern clothing on the rest of our journeys. Never knew what the deal was with them.

Back home in the Victor Valley, where I still live, there used to be a hardware store owner that was the good kind, had everything, so of course I was there often. It was called Victorville Hardware and also had a good line of small tractors. I mentioned the Pasquali to him with enthusiasm and he said he'd look into them.

A few months later he had a couple of Pasquali's and the following 4th of July, he pulled a hay wagon with lovely lasses in the local parade. That became an annual event for he and his beloved Pasquali.

He became an almost obsessed enthusiast and eventually drove his Pasquali across the U.S!

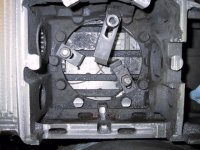

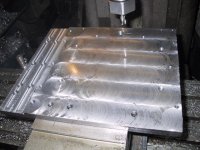

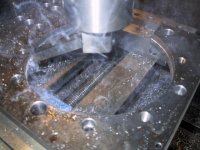

Nice to hear of them again and thanks for the links, and the photo essay of good work on a worthy little tractor, good memories......

Bob