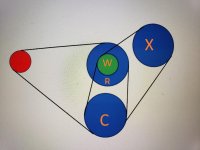

The blue pulleys are all the same 6" diameter.

The red pulley is 4" diameter, and so is the green pulley. The green is pulley is a smaller 'v' groove on the same pulley as the blue one. In other words, it is a 2 groove pulley made from a solid block of metal we'll call the RW pulley.

The pulley at the bottom is the driving pulley and is going 3000RPM.

So... all the 6" pulleys will spin the same 3000RPM. The red pulley will spin faster by the ratio of 6/4. Will the blue pulley R spin at 3000RPM or will it want to spin at the green 'W' pulley speed? Or will there be instant and constant 'disagreement' on the RW pulley and the belt starts slipping and smokin'?

Note that the belt can't just go to the X pulley from the C pulley in a straight line as it will contact the W pulley diameter; it has to go over the pulley.

The red pulley is 4" diameter, and so is the green pulley. The green is pulley is a smaller 'v' groove on the same pulley as the blue one. In other words, it is a 2 groove pulley made from a solid block of metal we'll call the RW pulley.

The pulley at the bottom is the driving pulley and is going 3000RPM.

So... all the 6" pulleys will spin the same 3000RPM. The red pulley will spin faster by the ratio of 6/4. Will the blue pulley R spin at 3000RPM or will it want to spin at the green 'W' pulley speed? Or will there be instant and constant 'disagreement' on the RW pulley and the belt starts slipping and smokin'?

Note that the belt can't just go to the X pulley from the C pulley in a straight line as it will contact the W pulley diameter; it has to go over the pulley.