Hey guys,

It has come to a pretty grim time for us, the operator who usually setup and run our Pfauter machines from the 60s has tested positive for Covid-19 and is in a very bad state right now - he's retiring in February so he´s most likely not coming back to work when he gets better.

I have run the machines before when we just did cylindrical spur gears so I have a basic understanding of how to operate the machine.

The boss asked me to atleast give it a shot at setting up the machine for a gear with a helix angle of 15 degrees.

I can´t seem to wrap my head around how to calculate what gears to add to the "differential feed".

My boss told me that the old operator used to have a Pfauter manual with alot of Index & Differential gear setups, however - this manual was accidentally sent off with a machine we sold.

Anyone out there who could point me in the right direction to correctly calculate this type of setup?

I have the machine constant for the differential which is - 8.952466

I have found a formula that was written by hand on a piece of paper which looks like this:

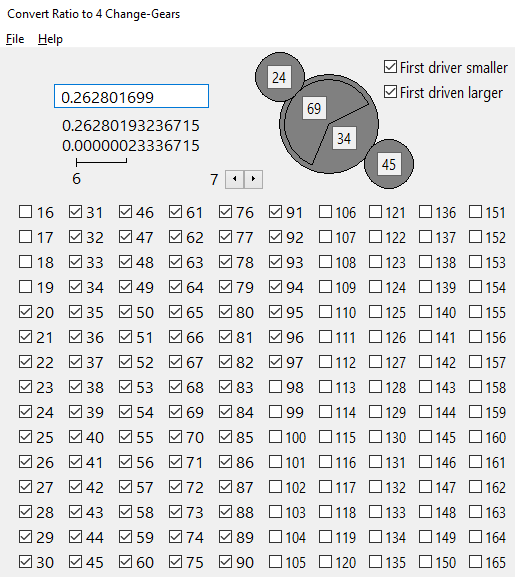

(8.952466 x Sin11Degrees) / Module 6.5 which results in 0.262801699 which he has separated like this:

0.262 | 801 | 699

How do I calculate what change gears to choose for this formula? I´m guessing the separation is to to be able to calculate a gear set which comes in as close as possible?

I hope I didn´t bombard you all with this question - which is my first post aswell.

Have a great evening you all,

cnctim_s

It has come to a pretty grim time for us, the operator who usually setup and run our Pfauter machines from the 60s has tested positive for Covid-19 and is in a very bad state right now - he's retiring in February so he´s most likely not coming back to work when he gets better.

I have run the machines before when we just did cylindrical spur gears so I have a basic understanding of how to operate the machine.

The boss asked me to atleast give it a shot at setting up the machine for a gear with a helix angle of 15 degrees.

I can´t seem to wrap my head around how to calculate what gears to add to the "differential feed".

My boss told me that the old operator used to have a Pfauter manual with alot of Index & Differential gear setups, however - this manual was accidentally sent off with a machine we sold.

Anyone out there who could point me in the right direction to correctly calculate this type of setup?

I have the machine constant for the differential which is - 8.952466

I have found a formula that was written by hand on a piece of paper which looks like this:

(8.952466 x Sin11Degrees) / Module 6.5 which results in 0.262801699 which he has separated like this:

0.262 | 801 | 699

How do I calculate what change gears to choose for this formula? I´m guessing the separation is to to be able to calculate a gear set which comes in as close as possible?

I hope I didn´t bombard you all with this question - which is my first post aswell.

Have a great evening you all,

cnctim_s

. Then I will pay Dan to make the match. Which he could do blindfolded.

. Then I will pay Dan to make the match. Which he could do blindfolded.