TheWolfOfWalmart

Plastic

- Joined

- Nov 2, 2018

So recently I was very fortunate to receive a free Sheldon R15 engine lathe- This will be my first foray into turning. Supposedly it runs fine but I still need to put in the circuit and wire the VFD to confirm- but I digest.

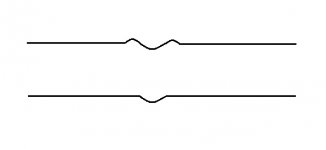

The ways have a couple sizable dents- Maybe a 1/4" wide- which, for the price of pretty much just the forklift rental, isn't a huge deal.

My due-diligence searching on the topic mostly just told me to not worry about it and make parts. My question is, would the leading edge of the carriage dive into the dent and heavily effect my parts? or is there enough bearing surface that it wouldn't be a big deal? I.E. how much should I expect them to effect my parts? I've stoned the ways and ensured that there aren't any burs, FWIW.

The ways have a couple sizable dents- Maybe a 1/4" wide- which, for the price of pretty much just the forklift rental, isn't a huge deal.

My due-diligence searching on the topic mostly just told me to not worry about it and make parts. My question is, would the leading edge of the carriage dive into the dent and heavily effect my parts? or is there enough bearing surface that it wouldn't be a big deal? I.E. how much should I expect them to effect my parts? I've stoned the ways and ensured that there aren't any burs, FWIW.