calderp

Aluminum

- Joined

- Jul 22, 2011

- Location

- New Orleans

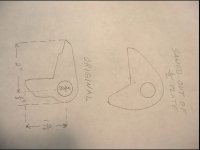

I just bought a Dake 1-1/2 B for a great price due to a missing handle and ratcheting pawl. Parts are available from Dake but at $350 I'll be paying more for the pawl and handle than I paid for the press which is a little hard to swallow and it would be an interesting exercise to fabricate a replacement. Is anyone with a Dake 1-1/2 or 1-3/4 willing to take two quick measurements for me? I can figure them out myself but it would save me a fair bit of fiddling is someone could give me a thickness measurement for the handle casting (Dake calls it a leverweight) at the point where it slides onto the shaft and a center to center measurement for the distance between the hole for the shaft and the hole for the pin that holds the pawl. A good photo of the pawl would also be appreciated.