Need to drill and ream for interference fit for some 3/8" dowels. Digging into the Machinery's Handbook I've found a recommended max ream size of .375" to a min of .3745" for a 3/8" standard, hardened, ground dowel pin.

Now looking at the dowel pins on McMaster, they are sized nominally at .375" with a diameter tolerance of +.0001" to .0003".

Looking at a 3/8" reamer on McMaster and it has a cutting diameter of .3750" with a cutting diameter tolerance from 0" to .0002".

If my math is correct, this means I could end up with a reamed hole diameter of .3752" and a dowel pin with a diameter of .3751", which equals a .0001" oversized hole to me.

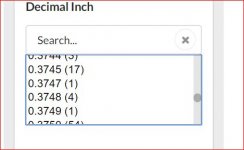

Looking at undersized reamers and the next closest size that I can find at Mcmaster is .3740", which is .0005" under the min recommended size in the Handbook. Browsing on MSC's website, and I can't find anything in between, and they don't even spec the cutting diameter tolerance.

What am I missing? I'm missing something.

Thanks!

Casey

Now looking at the dowel pins on McMaster, they are sized nominally at .375" with a diameter tolerance of +.0001" to .0003".

Looking at a 3/8" reamer on McMaster and it has a cutting diameter of .3750" with a cutting diameter tolerance from 0" to .0002".

If my math is correct, this means I could end up with a reamed hole diameter of .3752" and a dowel pin with a diameter of .3751", which equals a .0001" oversized hole to me.

Looking at undersized reamers and the next closest size that I can find at Mcmaster is .3740", which is .0005" under the min recommended size in the Handbook. Browsing on MSC's website, and I can't find anything in between, and they don't even spec the cutting diameter tolerance.

What am I missing? I'm missing something.

Thanks!

Casey