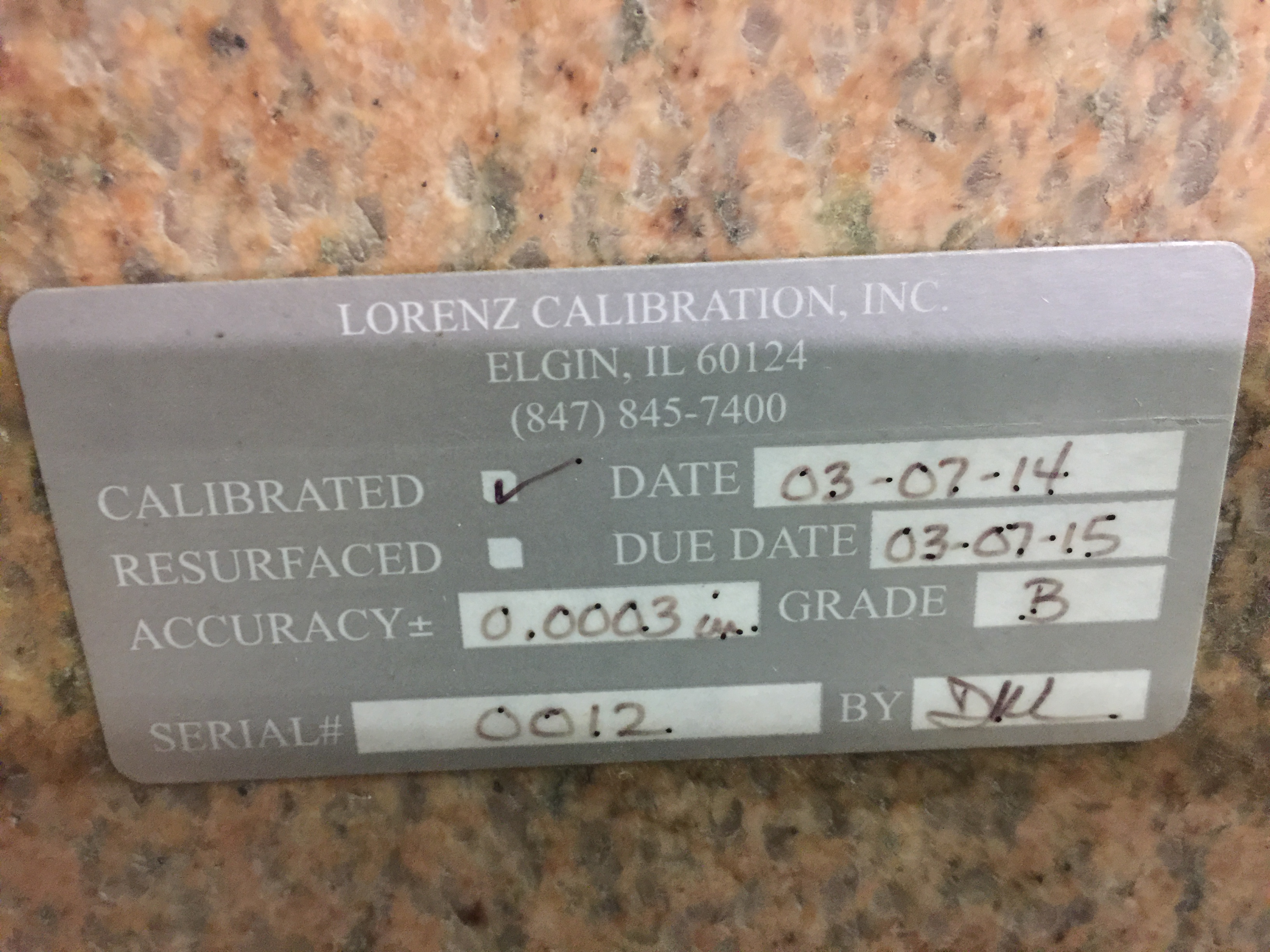

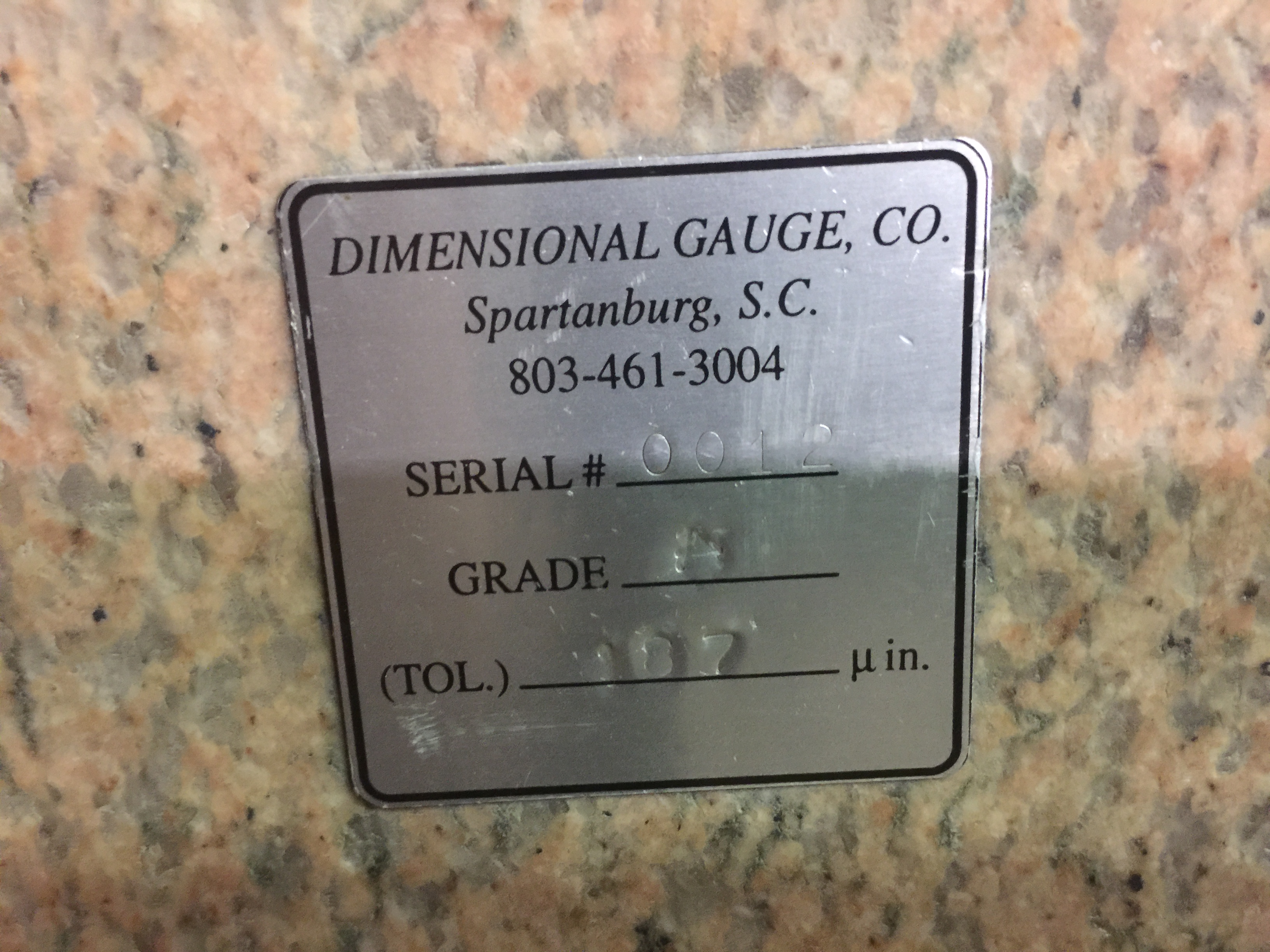

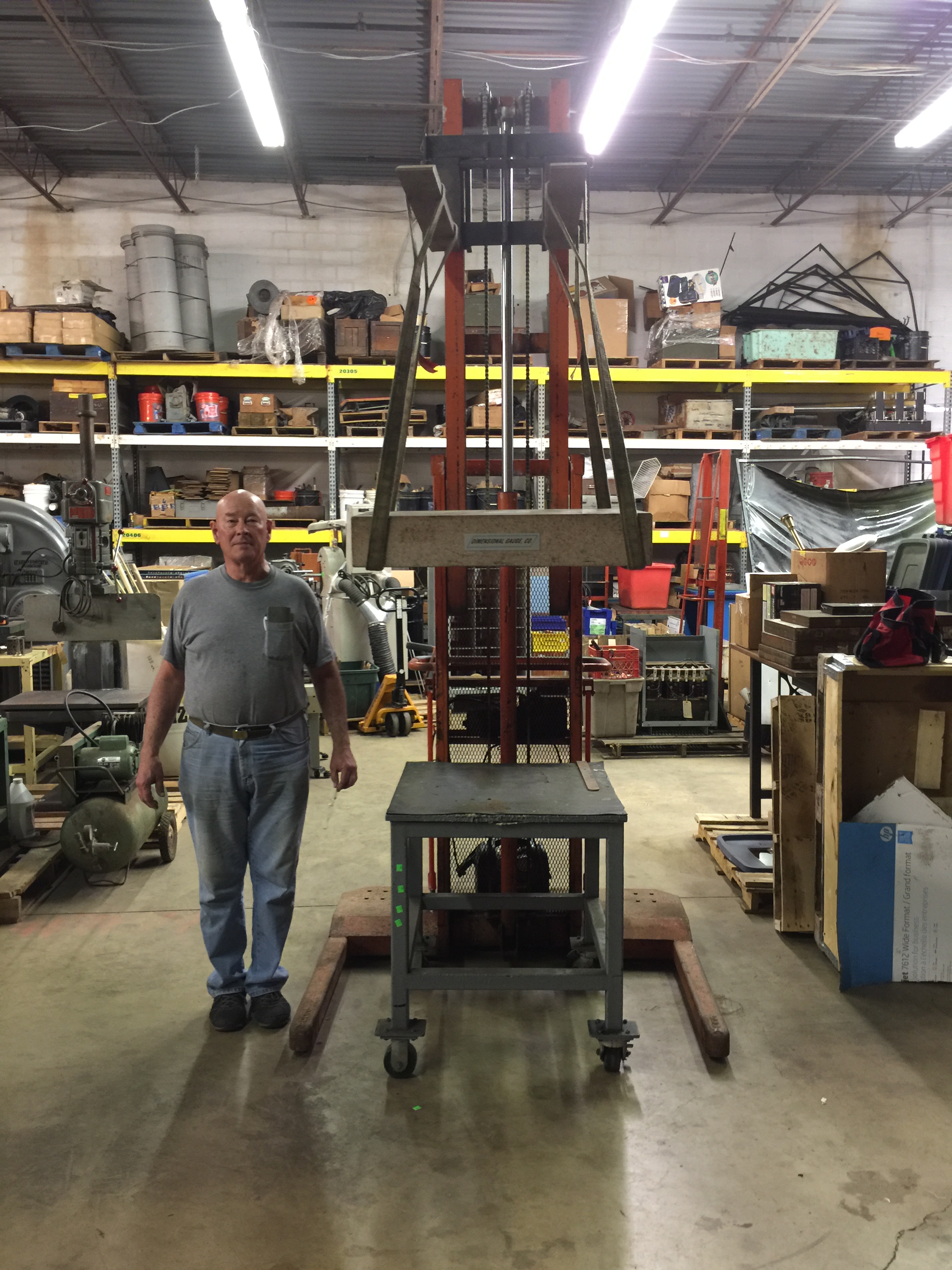

Getting ready to mount a 2'x3'x8" granite surface plate on something appropriate, and need to know minimum requirements, if any, beyond being strong enough so it won't collapse. For example, are "quality" granite surface plates made so they'll be just as flat when hung from both ends only, as they are when supported uniformly underneath? I'm asking because I have a great table in mind for it but I'd bought the table in order to mount some nice bench drills or other machinery and don't want to sacrifice it to hold a big rock if said rock would be just as happy on an old, beat-up wood workbench. Here's a pic of the 600-lb. table which I think may be overkill. It is shown on its way to be mechanically de-rusted.

Last edited: