NeilP

Plastic

- Joined

- Mar 4, 2012

- Location

- Jersey , Channel Islands

Full explanation follows...with the very last line being the actual questions .

I have an old SIP Belt drive air compressor, early 1990's.

A few months back the bottom end of the pump seized. it locked up and fuse tripped.

Stripped the pump last month, sorted out the bottom end and pump is now good as new.

The motor is a 1.5 -2.0 HP Single phase 240 volt domestic electric motor . In the UK, where standard single phase is 240 v

Motor is a twin capacitor type, 200MFD start cap, 30 MFD run capacitor.

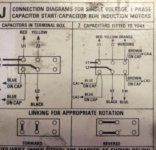

Motor is wired as per the LHS diagram in the attached photo.

When putting it back on the compressor, I noticed that the run capacitor had blown.

Before reconnecting, the drive belt I disconnected the run capacitor, and briefly spun it up.

Motor ran just fine.

I went to a local motor rewind company this morning and bought a new 30 MFD run capacitor.

At least that is what I asked for..

I have read this thread http://www.practicalmachinist.com/v...ifference-between-run-start-capacitor-102509/

and also posted there in the hope someone who know may come over to my thread here and give some advice

So I fitted the new capacitor, and motor ran up.

Connect the drive belt back up ...motor ran.

For about 30 seconds..still no real load on the pump...tank pressure was still sub 10 psi. I have over 400 litre capacity and it had barely begun to fill. Pump still spins free..it has not seized again or anything like that!

At that point I just walked away, will go back later today.

So why would the capacitor blow again?...have the motor rewind people simply given me the wrong capacitor type? or could there be something wrong with the motor windings?

What should I test for? shorts ? but I guess if there was anything like that, the motor would not have run to start with and I'd have blown the fuse instantly.

I have an old SIP Belt drive air compressor, early 1990's.

A few months back the bottom end of the pump seized. it locked up and fuse tripped.

Stripped the pump last month, sorted out the bottom end and pump is now good as new.

The motor is a 1.5 -2.0 HP Single phase 240 volt domestic electric motor . In the UK, where standard single phase is 240 v

Motor is a twin capacitor type, 200MFD start cap, 30 MFD run capacitor.

Motor is wired as per the LHS diagram in the attached photo.

When putting it back on the compressor, I noticed that the run capacitor had blown.

Before reconnecting, the drive belt I disconnected the run capacitor, and briefly spun it up.

Motor ran just fine.

I went to a local motor rewind company this morning and bought a new 30 MFD run capacitor.

At least that is what I asked for..

I have read this thread http://www.practicalmachinist.com/v...ifference-between-run-start-capacitor-102509/

and also posted there in the hope someone who know may come over to my thread here and give some advice

So I fitted the new capacitor, and motor ran up.

Connect the drive belt back up ...motor ran.

For about 30 seconds..still no real load on the pump...tank pressure was still sub 10 psi. I have over 400 litre capacity and it had barely begun to fill. Pump still spins free..it has not seized again or anything like that!

At that point I just walked away, will go back later today.

So why would the capacitor blow again?...have the motor rewind people simply given me the wrong capacitor type? or could there be something wrong with the motor windings?

What should I test for? shorts ? but I guess if there was anything like that, the motor would not have run to start with and I'd have blown the fuse instantly.