This is a subject that has attracted my interest. I saw different numbers being thrown about in posts like this so I became curious as to just what constituted a 75% thread and by extension, what constituted a 100% thread. I did some research and the deeper that I dug, the more confused I became. First, there are many tap drill tables out there and they do not always agree. Second, if you look into the standards, it is actually worse than the Wikipedia drawing that is shown in the original post. That drawing completely neglects tolerances and the different allowances that apply to the different classes of fit. What I could not find anywhere was any definitive statement of precisely what numbers were used to calculate the size of the thread that constituted either a 75% or a 100% thread size.

It quickly became apparent that I needed to analyze the various numbers in the published and accepted tap drill tables. That would be the only way to actually determine what those numbers were based on. So I decided to construct my own tap drill calculator so I could both do the calculations myself AND evaluate the true percentage that a given tap drill would actually provide. The evaluation of an actual tap drill is necessary because the calculated size and an actual, standard, available drill bit are only rarely the same. For most threads some compromise must be made. For some threads, too many in my humble opinion, that difference is all too large and the the actual percentage is quite different from the 75%. I have seen some commonly suggested "75%" tap drills that actually provide less than 70% or as much as 78% of the full thread form. These are tap drills that are published in a great number of "accepted" 75% tables.

I did construct my own tap drill calculator using Microsoft Excel. It allows the input of many different factors in the calculation. It does allow the calculation of tap drills for Vee threads of any cross sectional angle (60, 55, etc.) It does not use just a simple formula like the common one of Major Diameter minus the Pitch. It takes into account the:

Measurement System (English or Metric)

Nominal Major Diameter

TPI for English (inch) threads

Pitch for metric threads

% of Flat at the Crest

% of Fill at the Root

Thread Angle in degrees

Desired % of Full Thread

Each of these factors can be entered separately. It then calculates the Height of a full, sharp Vee thread, the Height of an actual, full thread, the Height of a thread of the desired percentage, a calculated Tap Drill Diameter in inches, a calculated Tap Drill Diameter in mm. It then uses table lookup functions to find actual, real world drill bits; both the nearest size under the calculated amount and the nearest size over the calculated size. It shows these nearest drill bit sizes in the same units that were selected as the first choice above (inches or mm).

It then shows a suggested tap drill bit using the one of the above, two choices that is closest to the calculated size. It shows that suggested drill bit size as a letter, number, fractional, of mm size. Then it displays the actual diameter of that drill bit in case you can't remember what the diameter of a L size bit is. Finally, it has a section where you can enter the actual drill bit that you wish to use. It shows that bit's diameter and the actual percentage of a full thread that it will produce for your thread. I still have a bit of work to do on that last section.

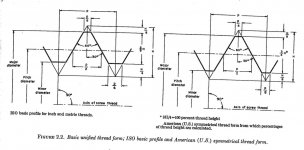

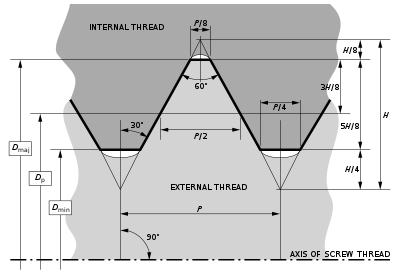

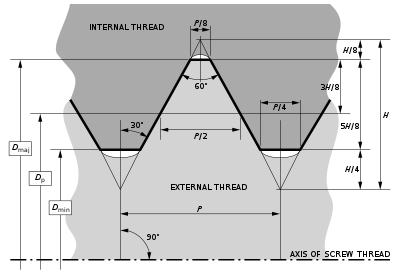

After I had partially completed this very complete tap drill calculator, I tried the sizes of the tap drills suggested by the many published tables and these trials convinced me that the published tables are calculated for threads with 1/8H flats on the crests and 1/8H fill at the roots. In short, almost all the published tables assume that the actual, full thread height is 3/4H or 75% of a sharp Vee thread. That means that they are intended to give you a thread that is 0.75 X 0.75 X the full height of a sharp Vee thread. That comes to 0.6525X or 65.25% of a sharp Vee thread.

That is less than 2/3s of the height of a sharp Vee thread and it took me some time and more research to convince myself that this was exactly what the published tables were doing. But it is. Now, there may be one or two odd-ball tables that give different results, but the vast majority are using this 65% factor or something very close. BTW, that is exactly 9/16 in fractional form.

That is somewhat long winded, but I think it should answer the OP's first question. I am sorry that I can not provide any better source for this information, but I am completely satisfied that it is correct. Perhaps if I were to spend hundreds or even thousands of dollars on an official source document, but that is too rich for my blood. Another conclusion that I came to in this search was that those official source documents are closely guarded, expensive, and not everything in them is published in more readily available sources like Machinery's Handbook or Wikipedia. I suspect this is by design to protect their income stream.

But this means that 5mm drill is 92%.

But this means that 5mm drill is 92%.