MicroTransaction

Plastic

- Joined

- Feb 10, 2020

- Location

- Dunedin, New Zealand

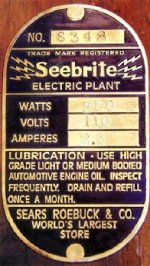

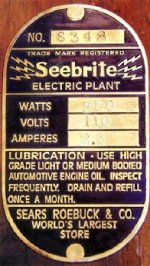

I've been wanting to know what techniques are used to create the brass nameplates you see on some older machinery (I think most newer stuff is aluminium). From what I've been able to find, there are 2 methods for generating the text/imagery, engraving and etching, and it seems to me that most nameplates are done with etching, but I'm not sure. In addition, some of the plates seem to be inkfilled with place in the background, and the colouring seems pretty resistant to stuff like paint-stripper, so I was wondering what method was used to get that colouring, since it doesn't seem to be paint. I'll try to summarise the questions below

My main questions are as follows:

- What process is used to form the lettering and decorations on nameplates like this

- What process is used to create the black ink-fill appearance

My main questions are as follows:

- What process is used to form the lettering and decorations on nameplates like this

- What process is used to create the black ink-fill appearance