How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

TpF thread callout

- Thread starter Mr.Bronze

- Start date

- Replies 23

- Views 8,530

Philabuster

Diamond

- Joined

- Jul 12, 2006

- Location

- Tempe, AZ

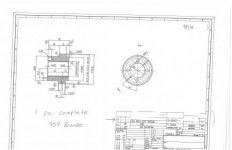

The part has an external tooth gear. The ID has only a 2mm chamfer. For some reason, this does not seem like this part would have an ID thread, but perhaps a spline? The 65mm dimension calls out the word (PITCH) after 6. Perhaps a 6 tooth spline with 65mm major.

I'm obviously guessing, but still does not look like a threaded part with the ID having a finish callout. A spline would make sense to have that callout.

I'm obviously guessing, but still does not look like a threaded part with the ID having a finish callout. A spline would make sense to have that callout.

The part has an external tooth gear. The ID has only a 2mm chamfer. For some reason, this does not seem like this part would have an ID thread, but perhaps a spline? The 65mm dimension calls out the word (PITCH) after 6. Perhaps a 6 tooth spline with 65mm major.

I'm obviously guessing, but still does not look like a threaded part with the ID having a finish callout. A spline would make sense to have that callout.

Agreed, I would hazard a guess they want a Trapezoidal Form spine not a thread.

MrSteve

Aluminum

- Joined

- May 26, 2014

- Location

- Boston/North Shore, MA, USA

ISO 4156-1:2005

Straight cylindrical involute splines?

Straight cylindrical involute splines?

JRIowa

Diamond

- Joined

- May 27, 2003

- Location

- Marshalltown, Iowa, USA

This is one of those times when a call to the customer is in order.

It doesn't make sense here, but where I worked, TPF stood for Temperature, Pressure, Flow. I don't think that they're sizing a control valve on that drawing.

JR

It doesn't make sense here, but where I worked, TPF stood for Temperature, Pressure, Flow. I don't think that they're sizing a control valve on that drawing.

JR

Gordon B. Clarke

Banned

- Joined

- May 29, 2010

- Location

- Denmark

This is one of those times when a call to the customer is in order.

JR

I agree. Phone or email the customer. I'm pretty sure it isn't a thread.

Limy Sami

Diamond

- Joined

- Jan 7, 2007

- Location

- Norfolk, UK

Still bell the client but;-

How about Tp = Trapezoidal, & F= Female ?

How about Tp = Trapezoidal, & F= Female ?

Last edited:

CountryBoy19

Stainless

- Joined

- Aug 14, 2012

- Location

- Bedford, IN

Could the "F" be for "female"? I know that's somewhat obvious on the print, but in standard prints we still use the "A" & "B" designations for male and female even though it's generally obvious.I'm kind of leaning towards ISO 30° Trapezoidal, but the F in the call out has me second guessing that idea.

FWIW, I too am just guessing; throwing out possibilities.

gregormarwick

Diamond

- Joined

- Feb 7, 2007

- Location

- Aberdeen, UK

Standard short form callout for Trapezoidal is TR, not Tp, so I'm thinking not trapezoidal whatever the hell it actually is...

Gordon B. Clarke

Banned

- Joined

- May 29, 2010

- Location

- Denmark

Try Googling splines and TPF

[R] natural splines

http://statweb.lsu.edu/faculty/marx/SKiP.pdf

Longitudinal Data Analysis - Google Boger

Seems more plausible than all the guess work No matter what you can't avoid contacting your customer unless you are "suicidal". Why are some so hesitant to contact a customer? You get to know them and they get to know you. I've found that "the personal touch" often makes the difference.

No matter what you can't avoid contacting your customer unless you are "suicidal". Why are some so hesitant to contact a customer? You get to know them and they get to know you. I've found that "the personal touch" often makes the difference.

[R] natural splines

http://statweb.lsu.edu/faculty/marx/SKiP.pdf

Longitudinal Data Analysis - Google Boger

Seems more plausible than all the guess work

No matter what you can't avoid contacting your customer unless you are "suicidal". Why are some so hesitant to contact a customer? You get to know them and they get to know you. I've found that "the personal touch" often makes the difference.

No matter what you can't avoid contacting your customer unless you are "suicidal". Why are some so hesitant to contact a customer? You get to know them and they get to know you. I've found that "the personal touch" often makes the difference.Modelman

Titanium

- Joined

- Sep 12, 2007

- Location

- Northern Illinois

Why are some so hesitant to contact a customer? You get to know them and they get to know you. I've found that "the personal touch" often makes the difference.

Some people want a sanity check before they contact the customer and then find they overlooked something blazingly obvious. Some people want some discussion of possibilities so they are sure to have all their questions answered in the first call.

Dennis

Gordon B. Clarke

Banned

- Joined

- May 29, 2010

- Location

- Denmark

Some people want a sanity check before they contact the customer and then find they overlooked something blazingly obvious. Some people want some discussion of possibilities so they are sure to have all their questions answered in the first call.

Dennis

I guess I'm not "some people"

I've no objection to my customers asking questions and they do often. I ask questions too. How else can misunderstandings be avoided?

I've no objection to my customers asking questions and they do often. I ask questions too. How else can misunderstandings be avoided?sfriedberg

Diamond

- Joined

- Oct 14, 2010

- Location

- Oregon, USA

Yes, Gordon, you are definitely "some other person".

Gordon B. Clarke

Banned

- Joined

- May 29, 2010

- Location

- Denmark

Yes, Gordon, you are definitely "some other person".

Anything in this thread I've written that you disagree with?

Modelman

Titanium

- Joined

- Sep 12, 2007

- Location

- Northern Illinois

I guess I'm not "some people"I've no objection to my customers asking questions and they do often. I ask questions too. How else can misunderstandings be avoided?

Gordon, let me try this more s l o w l y so maybe you understand it. No one has said they won't ask the customer if they need to. What they are looking for is some discussion to clarify their thinking BEFORE they talk to the customer, to be sure they are not asking really obvious stupid questions, and also to be sure they ask all the right questions to get the information they need in the first call.

Dennis

LKeithR

Stainless

- Joined

- Sep 1, 2011

- Location

- Langley, B.C.

This is one of those times when a call to the customer is in order...

Yeah, if there's something on the print you don't understand the "first" thing you do is call the customer. Guessing at something like this isn't going to win you any brownie points.

Still boggles my mind how many people are afraid to "communicate" with their customers--there's no guilt or shame in having questions...

Limy Sami

Diamond

- Joined

- Jan 7, 2007

- Location

- Norfolk, UK

Hi there Mr Bronze

What's the SP on this call out then?

What's the SP on this call out then?

This is one of those times when a call to the customer is in order.

It doesn't make sense here, but where I worked, TPF stood for Temperature, Pressure, Flow. I don't think that they're sizing a control valve on that drawing.

JR

I am all about calling my customers with questions, but with this one in particular, he sends me stuff that he is not sure of either. I translate all sorts of stuff for him, and he likely does not know off the top of his head either what the end part will look like.

Here is the full print

I do think there is a gear on the outside of it(125 pitch dia, z=50, 2.5 mod 20° pressure angle, if i am correct), but I am pretty sure it is a thread on the ID - specifically a left handed thread, with a mysterious call out for it. I will end up having to call the customer to have them chase it back up the chain for clarification it looks like - if it has everyone here scratching their heads.

Attachments

Last edited:

JRIowa

Diamond

- Joined

- May 27, 2003

- Location

- Marshalltown, Iowa, USA

I will end up having to call the customer to have them chase it back up the chain for clarification it looks like - if it has everyone here scratching their heads.

I quit scratching the bare spot years ago.

Used to have the same problem with tooling drawing for our German (Ex-Cell-O) FWD equipment. They were taking the German drawings, copying, and then doing mark-ups. Too cheap to buy a PC with AutoCAD back then.

JR

readysetgo

Plastic

- Joined

- Sep 15, 2018

- Location

- Esfahan

Similar threads

- Replies

- 10

- Views

- 638

- Replies

- 6

- Views

- 406

- Replies

- 1

- Views

- 159

- Replies

- 3

- Views

- 392