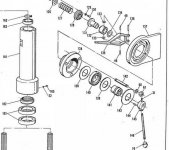

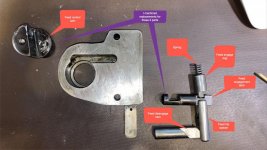

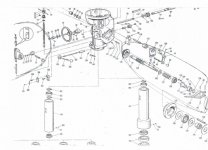

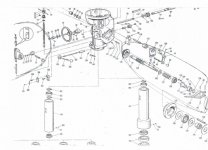

Interesting coincidence. I have been working on the same exact part on my 847 over the past 2 days. I just got it working yesterday. I'll add some pics and vids of mine via a google photos album. I noticed you weren't showing the spring in your parts layout. Do you have it? It's an important part of the overall engagement/disengagement. The attached pic shows the correct orientation of the parts in the feedlock housing. The video in this album should give you a good sense of the behavior to expect. You actually need to push up a bit more firmly than you might expect if you haven't done it before and aren't used to it yet.

Wells Index autofeed engagement clutch - Google Photos

The spring above the feed engage dog is vital to get it to slide down capturing the feed engagement latch then when the quill reaches the endstop, it presses down on the lever underneath the mechanism which presses up on the feed trip spaces and in turn on the feed engage dog to release it. Keep in mind that the feed engagement latch is what is pressing the brass clutch lever (wishbone shaped piece) over. That was specifically what I didn't realize because I couldn't push that in by hand so until I got the whole mechanism back together and felt how much pressure was needed, it finally all made sense.

Put lots of grease back on everything and good luck.

Just an WAG

Just an WAG