Hey guys I'm needing opinions on who you think makes the most quality reamer holder. I was going to buy a Bald Eagle setup, but have seen a couple bad reviews in other forums. I also like the JGS, but I don't know if hands free is the way to go or not? Any help would be greatly appreciated!

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for opinions on floating reamer holders

- Thread starter Turner421

- Start date

- Replies 33

- Views 12,773

300sniper

Hot Rolled

- Joined

- Nov 14, 2006

- Location

- Greenwood, Ca

JGS worked great for me. I finally wore one out and they rebuilt it to their newer version, which also works great.

pat_j0nes

Aluminum

- Joined

- Sep 9, 2018

- Location

- Colorado, US of A

Been using a JGS for 10 years now. I'm unfamiliar with the Bald Eagle, but I prefer my JGS to the Manson the shop owns.Hey guys I'm needing opinions on who you think makes the most quality reamer holder. I was going to buy a Bald Eagle setup, but have seen a couple bad reviews in other forums. I also like the JGS, but I don't know if hands free is the way to go or not? Any help would be greatly appreciated!

Sent from my Pixel 2 using Tapatalk

Illinoyance

Stainless

- Joined

- Aug 24, 2015

Used Glenzer or Scully Jones floating holders are WAY better than what is now being sold to gunsmiths.

mike in co

Plastic

- Joined

- Jul 18, 2007

- Location

- sun city

i am in the ptg line when it comes to floating holders.

i built my own but lost it to a fire, nought the ptg and have been happy

built a national championship rifle with it.

i built my own but lost it to a fire, nought the ptg and have been happy

built a national championship rifle with it.

Used Glenzer or Scully Jones floating holders are WAY better than what is now being sold to gunsmiths.

Do you have any picture of your reamer holders ?

Thanks

Hal

GenePoole

Cast Iron

- Joined

- Dec 8, 2012

- Location

- St. Louis, MO

Do you have any pictures of your reamer holders ?

Thanks

Hal

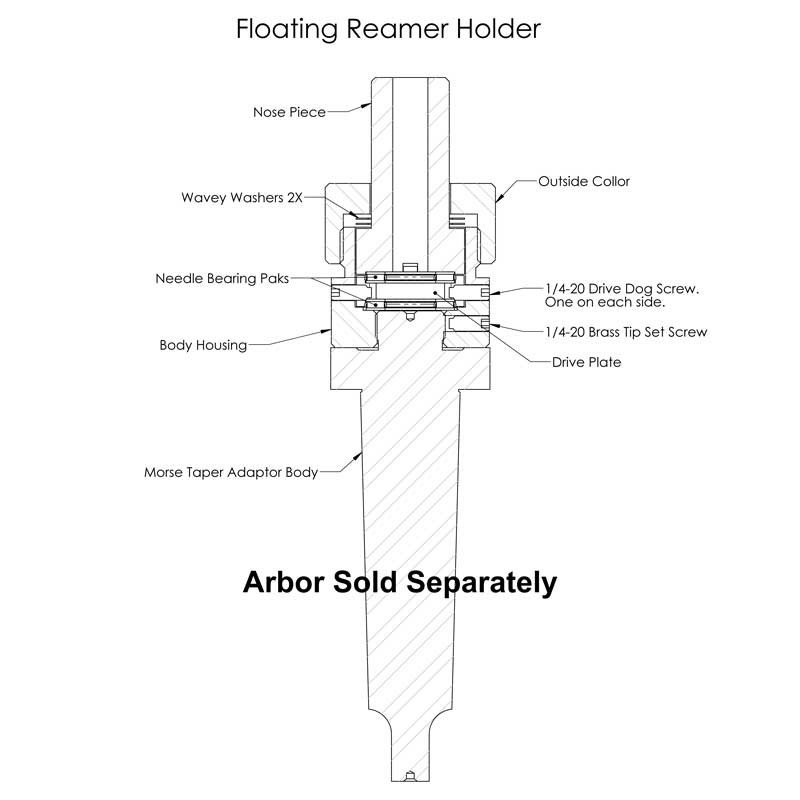

PTG reamer holder:

PTG Standard Floating Reamer Holder Head - Pacific Tool and Gauge

tooleyrifles

Plastic

- Joined

- Feb 25, 2018

Illinoyance

Stainless

- Joined

- Aug 24, 2015

Do you have any picture of your reamer holders ?

Thanks

Hal

I will try o get pix on Monday.

mike in co

Plastic

- Joined

- Jul 18, 2007

- Location

- sun city

what's pushing the holder ? i see the tool post in front ??

I'v used a simple pusher for 35+ years.View attachment 251286

wesg

Titanium

- Joined

- Nov 4, 2004

Looks like a tailstock to me.

tooleyrifles

Plastic

- Joined

- Feb 25, 2018

what's pushing the holder ? i see the tool post in front ??

When I set the Haas up I wanted the same setup as I use on my manual machines for finish reaming. I want my hand on both the reamer and the hand wheel on the tail stock. Each provides different information. The tail stock has a graduated hand wheel so no indicator setup need to get the chamber to the correct depth. It has a morse taper adapter that is the pusher. That was the lazy way out this time. I've taken drill chuck arbors and made pushers out of them in the past. When the rough cycle is done the saddle moves into alignment for the tail stock set up. That's tool #5 in the inventory. Free up the Z axis turn the coolant on and go to work.

When I set the Haas up I wanted the same setup as I use on my manual machines for finish reaming. I want my hand on both the reamer and the hand wheel on the tail stock. Each provides different information. The tail stock has a graduated hand wheel so no indicator setup need to get the chamber to the correct depth. It has a morse taper adapter that is the pusher. That was the lazy way out this time. I've taken drill chuck arbors and made pushers out of them in the past. When the rough cycle is done the saddle moves into alignment for the tail stock set up. That's tool #5 in the inventory. Free up the Z axis turn the coolant on and go to work.

?????????????

wesg

Titanium

- Joined

- Nov 4, 2004

Yeah, upon further review...

Is there a separate tailstock, and the toolpost just carries the torque arm for the reamer? Or is there a block with a pusher controlled by the 'handwheel' for the carriage?

Is there a separate tailstock, and the toolpost just carries the torque arm for the reamer? Or is there a block with a pusher controlled by the 'handwheel' for the carriage?

tooleyrifles

Plastic

- Joined

- Feb 25, 2018

Sorry I haven't checked a box to get notified of a response.

everything is part of the tool holder.

everything is part of the tool holder.

Butch Lambert

Titanium

- Joined

- Oct 30, 2002

- Location

- Poetry Texas USA

Dave wants the reamer to follow the hole, drilled, bored, or whatever. his setup does not allow the reamer to do anything, but to follow the hole. I believe his pusher is flat where it bears on the reamer.

Dave chambers more barrels in a week than most do in a lifetime.

Dave chambers more barrels in a week than most do in a lifetime.

Grizzlypeg

Aluminum

- Joined

- Aug 20, 2012

- Location

- Canada

I made a homemade copy of the Bald Eagle floating reamer holder, but with a minor change. Instead of having the reamer holder have an internal rear flat surface which bears against the rounded pusher in the tailstock, I instead pressed a ball bearing into the rear of the holder, and that bears against a flat pusher. My reasoning being that if the pusher is rounded (as in the Bald Eagle design), it will bear pressure off centre on the reamer holder, if the reamer holder floats off centre. If its the opposite way around as I made it, then the reamer holder will always have pressure centred on the reamer, even if it is deviating from the centre of the pusher as it floats to follow the bore. Plus, it was easier to push a hardened ball bearing into a hole, than machine a hole with a perfect internal flat surface for the pusher to bear against.

Illinoyance

Stainless

- Joined

- Aug 24, 2015

Do you have any picture of your reamer holders ?

Thanks

Hal

The left item is a Glenzer floating tap driver adapted to an ER32 collet chuck.

The middle 2 items are Scully Jones MT x MT holsers. The right item is Glenzer MT x MT.

If I were using one of the MT holders I would use 7/16 split drill driver or 1/8 pipe split tap driver to hold the reamer. The flats on the reamer will not engage those drivers. I consider that a safety measure. The grip the driver has on the reamer depends on how hard you seat the driver into the taper. These holders are designed for radial float only. If the retaining nut on the back of the Scully Jones holder is backed off a bit it will allow some angular float.

I think the PTG holder is based on the Glenzer design, omitting some of the bearing balls.

Last edited:

MonCeret Gunsmit

Aluminum

- Joined

- Aug 23, 2018

- Location

- E. TN

Is your "pusher" a dead center, or did you make a ball nosed pusher?I'v used a simple pusher for 35+ years.View attachment 251286

partsproduction

Titanium

- Joined

- Aug 22, 2011

- Location

- Oregon coast

It seems like an oldham coupler would serve well, the few floating holders I've seen didn't seem to float sideways without significant drag.

An oldham can be built with dovetail cutters, should be easy enough.

An oldham can be built with dovetail cutters, should be easy enough.