I've been thinking of this for some time now, years. I'm not a gunsmith but have always wondered why this is not common in the re-barreling of rifles. For example, instead of cutting a tenon and threading why not just sleeve and shrink fit? I've added a 3D model for further explanation. I'm sure there would be a massive amount of torque in the barrel while accelerating a mass down the riffling but surely it's not more than friction fit can handle. Maybe, the fit can be made and then pinned with an off-center cross pin drilled through the action/sleeve.

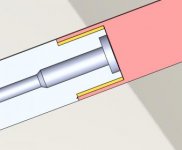

Color Code:

White - Barrel

Brass - Sleeve

Red - Action

Color Code:

White - Barrel

Brass - Sleeve

Red - Action