homebrew.357

Aluminum

- Joined

- Nov 4, 2013

- Location

- New Zealand

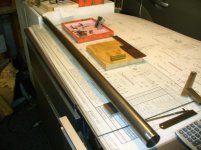

Hi all, yep I`m making a sharps rifle on my lathe, what is the best rifling twist for the 45-70 cartridge with black powder, I can get 1 in 24" and a max barrel length of 25". All the new barrels are 1in 18", some say a fast twist for this rifle. Barrel steel is 1214 ,nice for cut rifling and also what throat lead in from chamber end to rifling. Just looking for imfo before I start making this barrel, Just a home machinist, have already made a Hawken Plains rifle on my lathe, shooting good.  Homebrew.357.

Homebrew.357.

Homebrew.357.

Homebrew.357.

so did some a bullet casting for my .308, and .3030, 160gr lino type , just have to get some gas checks and powder, Varget ,2208, then test on the range,

so did some a bullet casting for my .308, and .3030, 160gr lino type , just have to get some gas checks and powder, Varget ,2208, then test on the range,

and they are on the way.

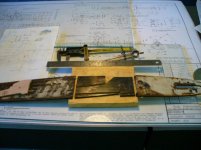

and they are on the way. So while I was waiting went to work on the side plate, this I made out of a chain saw bar. Theses are very hard steel, just what I wanted, so I can reharden and temper leaving a nice surfaces finish. The blade was just the right thickness so cut a chunk out with my angle grinder and annealed it with my blow touch so I could cut it and shape it, but will leave a bit for fitting. Slowly getting there, the pic`s, Homebrew.357.

So while I was waiting went to work on the side plate, this I made out of a chain saw bar. Theses are very hard steel, just what I wanted, so I can reharden and temper leaving a nice surfaces finish. The blade was just the right thickness so cut a chunk out with my angle grinder and annealed it with my blow touch so I could cut it and shape it, but will leave a bit for fitting. Slowly getting there, the pic`s, Homebrew.357.

Cheers,

Cheers,

Cheers,

Cheers,