npolanosky

Cast Iron

- Joined

- Apr 9, 2016

- Location

- USA, FL

I just noticed an odd issue on my VM.

I am getting faceting on g2/g3 arcs, but seemingly only in specific places.

It seems to happen only in the upper left quadrant of the part. I am digging in further to see if it happens in both directions and at different feedrates.

It happens only on arcs, straight lines on the diagonal seem ok.

I already eliminated it as a programming issue (I am getting arcs, not lines, and it happens regardless of g187 setting), this is either something weird in the control or more likely a mechanical issue.

Is this indicative of bad thrust bearings? Bad encoder? Something else? It's just odd to me, everything seems to work perfect and hold dimensions except for this.

I have no measurable backlash. Everything is nice and rigid as far as I can tell.

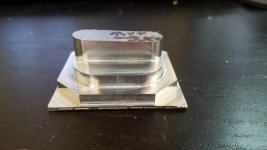

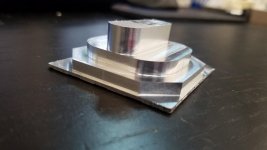

I cut a small test part, you can see the difference from corner to corner. I will run further tests today at varying feedrates with different tools.

I am getting faceting on g2/g3 arcs, but seemingly only in specific places.

It seems to happen only in the upper left quadrant of the part. I am digging in further to see if it happens in both directions and at different feedrates.

It happens only on arcs, straight lines on the diagonal seem ok.

I already eliminated it as a programming issue (I am getting arcs, not lines, and it happens regardless of g187 setting), this is either something weird in the control or more likely a mechanical issue.

Is this indicative of bad thrust bearings? Bad encoder? Something else? It's just odd to me, everything seems to work perfect and hold dimensions except for this.

I have no measurable backlash. Everything is nice and rigid as far as I can tell.

I cut a small test part, you can see the difference from corner to corner. I will run further tests today at varying feedrates with different tools.