shaffin

Aluminum

- Joined

- Jul 15, 2011

- Location

- Barrie, Ontario, Canada

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hello,

On my HAAS TM1, it states on the spindle cover that it support 40 taper with dimensions for CT, BT and DIN/ISO tooling - does this mean that I can use both CT and BT tooling with the specified pull studs????

Thanks,

Shaffin.

Thank you all for your comments. I dont have a tool changer with my machine, its a manual change that I perform so thinking that the studs are all 45 degree that I would be abel to use both BT40 and CAT40 tooling :-(

If you don't have a tool changer, (you didn't say that in the first post) then I think you can use both tool holders. The spindles are the same I believe. The only difference would have been the fingers on the tool carrousel, but you don't have one!

Mike

Hi Mike,

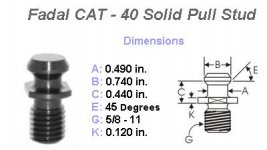

You're quite correct. Most MTB use a common Draw Bar arrangement, and make up for the length difference from small end of taper to the face of the flange closest to the spindle nose, of the various tool holder types, with the pull studs. The attached pictures show pull studs for BT40 and CAT40, for use with a Fadal machining centre.

View attachment 90524 View attachment 90525

Regards,

Bill

Hi Shaffin,

I've converted many CT machines imported from the US, to BT which is the most common configuration in Australia. It's not a difficult exercise, but it requires the Spindle Nose Drive dogs and the Tool Change grippers to be changed.

Regards,

Bill

Just to clarify, for a Haas machine, the spindle nose drive dogs work for either BT or CT tooling. The drive dogs are not replaceable.

Hi haastec,Just to clarify, for a Haas machine, the spindle nose drive dogs work for either BT or CT tooling. The drive dogs are not replaceable.

Hi haastec,

I haven't had the opportunity to convert a Haas to BT from CAT here in Australia, but when you say that the Drive Dogs aren't replaceable, are you saying that they're a machined feature of the Spindle Nose? If so, I'd see that as a poor design feature. I'm sure someone, somewhere would have driven an empty spindle into a fixture, or workpiece and wrecked existing Drive Dogs, or for some other reason you may want to remove the drive dogs from the Spindle Nose. I often remove the drive dogs when working on a machine that has a doubtful M19 position. With the dogs removed, a tool can be changed into the spindle (machines with a Tool Changer of course) and then observed if the dogs can be replace without interference with the tool in location.

The correct setup of drive dogs for a CAT holder prevents the tool holder from being loaded into the spindle orientated 180degs incorrectly. This feature is to prevent Boring Bar tools used with a G76 Boring Cycle being loaded into the Spindle orientated incorrectly. I'm pretty sure that a machine that was originally configured for BT tooling, won't accept a correct CAT tool because of the Drive Dogs for the BT configuration. But I think the inverse to that is possible.

Regards,

Bill

I would think that if you are going to run one into a fixture or vice so hard that it destroys the dogs, it will destroy the dog mounting slots on the removable ones too.

It's 6 of one and a half dozen of the other. Never destroyed one yet.

Mike

Hi Mike,

Its not at all the same. If, as haastec is saying, the drive dogs of a Haas spindle are not replaceable, then you're stuffed even with minimal damage. If, for whatever reason, the drive dogs of any other breed of machining centre where they are bolted to the spindle nose are damage, then you can simply unbolt old and replace them with new units. If replacing the drive dogs is all that's required, then its a low cost repair.

There are numerous methods by which the drive dogs get damaged. I repair CNC machines, and one repair I've done many times over the years, is replacing Spindle Nose drive dogs damaged due to the M19 position being out of kilter.

Further, if correct to standard CAT tooling is being used, and the correct drive dogs for BT standard are in place, then the CAT tooling shouldn't mount. The only correct way where either CAT or BT tools would mount, is if the configuration of the drive dogs was for CAT. In this case both the CAT and BT tooling will mount.

Regards,

Bill

Hi haastec,

I haven't had the opportunity to convert a Haas to BT from CAT here in Australia, but when you say that the Drive Dogs aren't replaceable, are you saying that they're a machined feature of the Spindle Nose? If so, I'd see that as a poor design feature. I'm sure someone, somewhere would have driven an empty spindle into a fixture, or workpiece and wrecked existing Drive Dogs, or for some other reason you may want to remove the drive dogs from the Spindle Nose. I often remove the drive dogs when working on a machine that has a doubtful M19 position. With the dogs removed, a tool can be changed into the spindle (machines with a Tool Changer of course) and then observed if the dogs can be replace without interference with the tool in location.

The correct setup of drive dogs for a CAT holder prevents the tool holder from being loaded into the spindle orientated 180degs incorrectly. This feature is to prevent Boring Bar tools used with a G76 Boring Cycle being loaded into the Spindle orientated incorrectly. I'm pretty sure that a machine that was originally configured for BT tooling, won't accept a correct CAT tool because of the Drive Dogs for the BT configuration. But I think the inverse to that is possible.

Regards,

Bill

Over 20 years using Haas without issue. But, if you refuse accept that, I will put my Haas up for sale right away and look for another machine!

Cheers

For a Haas spindle, the drive dogs and spindle taper are machined from the same piece of material. As stated previously, the Haas spindle/drawbar combo will accept either CT or BT tooling without any modifications assuming that the correct pull stud is being used for each version and the 180 degree orientation does not apply either. When configuring the machine, the only differences are with the tool changer fingers (CT or BT) and the tool change height location.

Is this right or wrong? It is different than what you are used to, but much smarter people than I design and engineer these machines, so I am not one to say either way. To my knowledge, this is the way Haas has always built their spindles. I have been working on them for 15+ years and I have yet to replace a spindle due to damaged drive dogs. I have seen them worn and beat up some, but still very functional.

As stated in my reply to machineit2, CAT tool holders built to their correct standard, and when correct CAT style drive dogs are used, will only mount in the spindle orientated one way, and won't mount if the spindle nose is configured BT via BT style drive dogs. I accept what you're saying, that either tool will mount into the spindle, but this can only be if Haas make all their spindles configured with CAT dimension drive dog features, or have thrown convention to the wind altogether, and have designed the drive dog dimensions to accept CAT tooling orientated either way.

I've not said that the drive dogs lose their functionality due to wear or damage, but they may. And I agree that the drive dogs would have to be in very bad shape to warrant the time and expense of changing a spindle. Clearly its desirable to have the option of easily swapping out relatively cheap, replaceable drive dogs, if required, during routine maintenance.

Regards,

Bill

For a Haas spindle, the drive dogs and spindle taper are machined from the same piece of material.

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.