riseandgrind

Cast Iron

- Joined

- Apr 15, 2008

- Location

- Anza, CA

How to remove HAAS DC shuttle in/out motor end cap

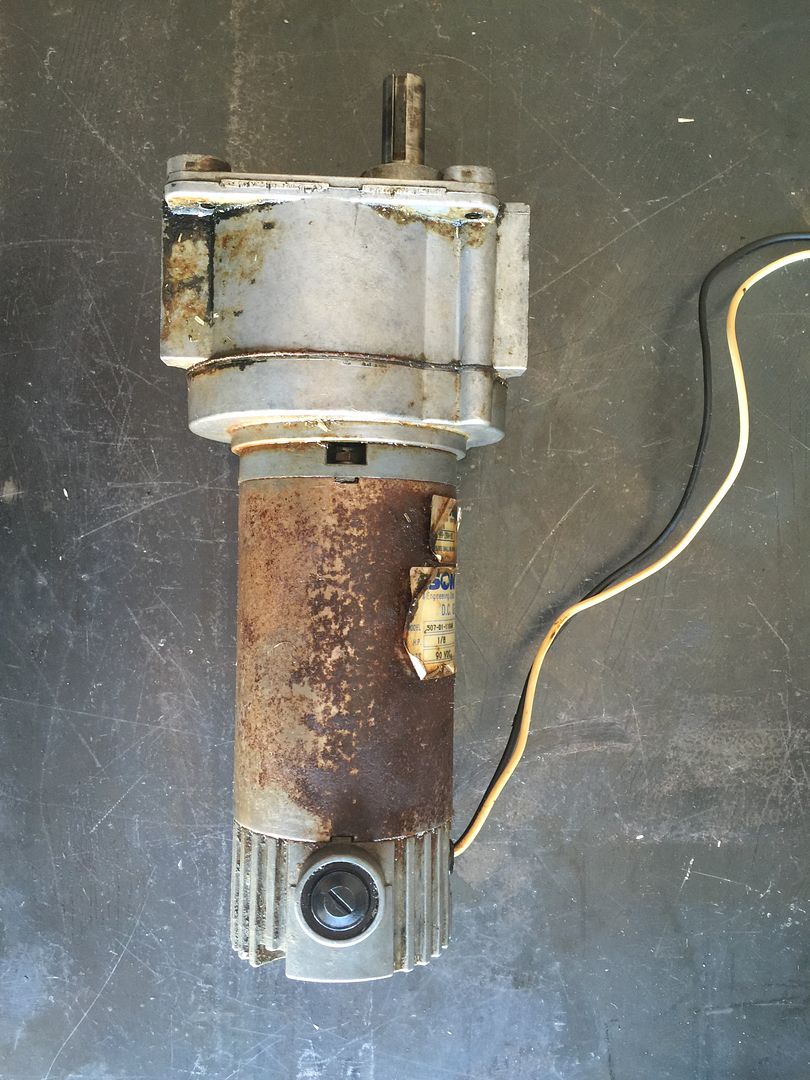

Like the thread says. I've been having alarm 113 and 114 issues. We believe the root of the problem is a loose set screw on the steel arm that mounts onto then shuttle in/out motor. The shuttle slides towards the spindle and alarms out just a hair before tripping the switch. If I push up on the arm that moves the shuttle about 1/4 inch I can watch the switch change to a 1 on the diagnostics screen. While doing that is when I noticed the arm could slide back and forth on the shuttle motor shaft. Not good. Accessing the set screw is a nightmare.

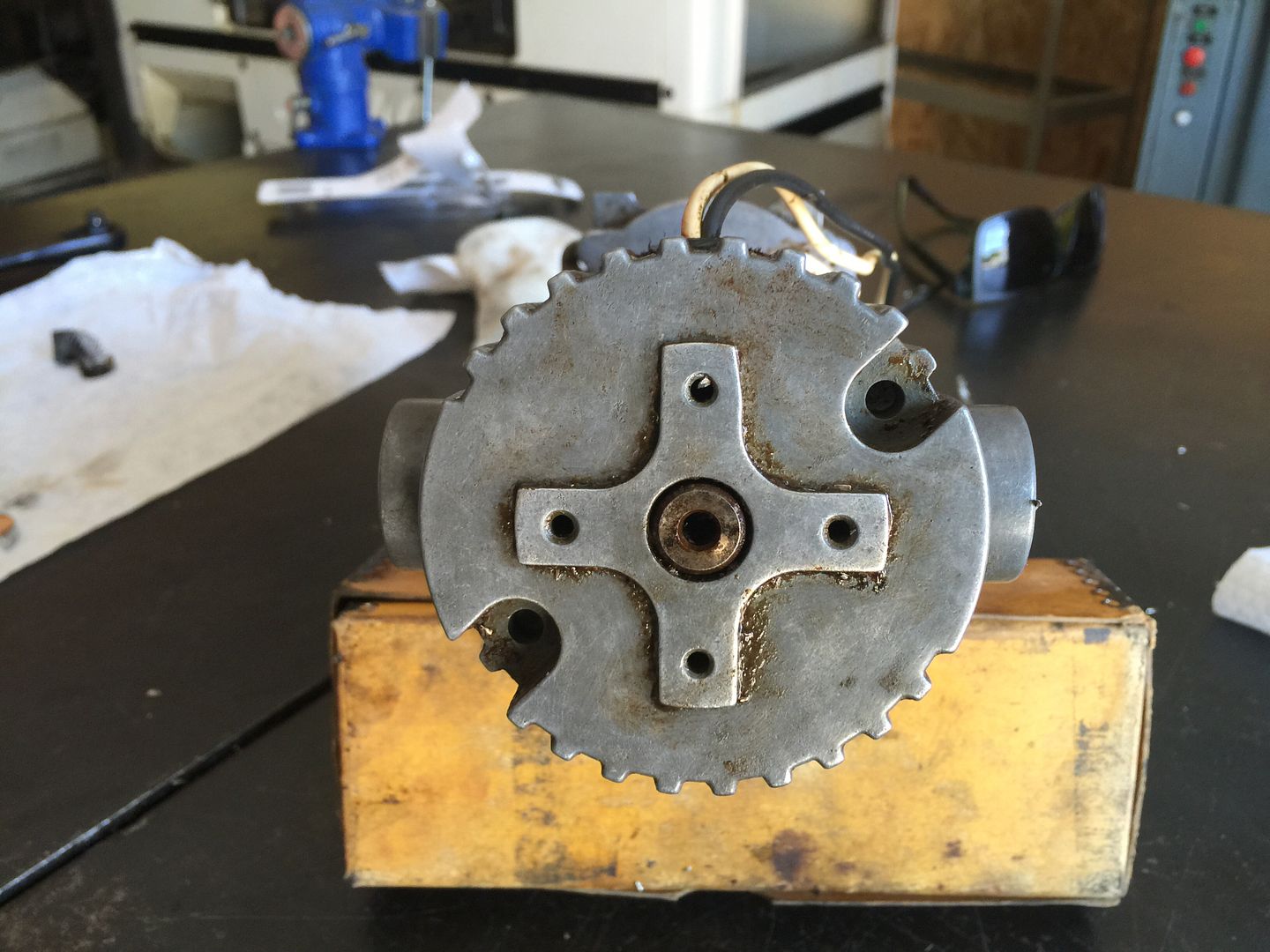

I pulled the motor since that was fairly simple and cleaned the brushes. The motor was working, although it didn't seem fast. Anyhow since the motor is out I figured I should really clean the contacts good. But I can't figure out how to remove the end cap off the motor so I can clean the armature. Bearing puller? I didn't see any screws. Almost looking like I need to disassemble the whole motor from the front side by the output shaft?

Any help? Do I need to do this? Also what size Allen for the damn set screw. Service manual says 1/8 but I think it's to big. Not sure can barely get at it even with a 10" extension and socket Allen.

It's a 1993 HAAS VF0

Like the thread says. I've been having alarm 113 and 114 issues. We believe the root of the problem is a loose set screw on the steel arm that mounts onto then shuttle in/out motor. The shuttle slides towards the spindle and alarms out just a hair before tripping the switch. If I push up on the arm that moves the shuttle about 1/4 inch I can watch the switch change to a 1 on the diagnostics screen. While doing that is when I noticed the arm could slide back and forth on the shuttle motor shaft. Not good. Accessing the set screw is a nightmare.

I pulled the motor since that was fairly simple and cleaned the brushes. The motor was working, although it didn't seem fast. Anyhow since the motor is out I figured I should really clean the contacts good. But I can't figure out how to remove the end cap off the motor so I can clean the armature. Bearing puller? I didn't see any screws. Almost looking like I need to disassemble the whole motor from the front side by the output shaft?

Any help? Do I need to do this? Also what size Allen for the damn set screw. Service manual says 1/8 but I think it's to big. Not sure can barely get at it even with a 10" extension and socket Allen.

It's a 1993 HAAS VF0

)has been removed. This also means there should be no resistance against the clutch itself to be a contributing factor.

)has been removed. This also means there should be no resistance against the clutch itself to be a contributing factor.