DeSelle

Cast Iron

- Joined

- Oct 23, 2006

- Location

- Midlothian, TX

Hi All,

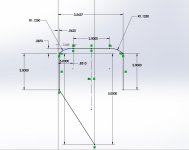

I am attempting to mill a simple key in the side of a shaft. Its woodruff like in that it has radii at the start and end and a flat on the bottom but dimensionally its not a woodruff. The shaft diameter is 1.9375 and I have zero at the left end of the bar, front edge and top edge I am cutting a key that is .287 deep starting .0625 from the end with a 1.125 radius at the start end. The flat across the bottom is 2" long and it ends with the same 1.125 radius. The error I get is the 367 cutter interference error but the radius I need to mill is 1.125 and the cutter is a 2" diameter so I should be ok? If I drop the cutter diameter in the offsets to 1" it works. Any thoughts? 2009 Haas VF7

Thanks Nathan

%

o07757

T02M6

(2 inch side cutter .25 thick)

G90G54G00X2.00Y-5.000

S200M3

G43H02Z-.7187M8

G42G01X0.0625Y-2.00D02F2.0

G1Y0.00

G2X.8131Y.287R1.125

G1X2.8131

G2X3.5637Y0.00R1.125

G1Y-2.00

G1X2.00Y-5.00

G1Z-1.21875

G1X.0625Y0.00

G2X.8131Y.287R1.125

G1X2.8131

G2X3.5637Y0.00R1.125

G1Y-4.00

G40X2.00Y-5.00

G00Z2.00M9

G53G49Z0M5

M30

%

I am attempting to mill a simple key in the side of a shaft. Its woodruff like in that it has radii at the start and end and a flat on the bottom but dimensionally its not a woodruff. The shaft diameter is 1.9375 and I have zero at the left end of the bar, front edge and top edge I am cutting a key that is .287 deep starting .0625 from the end with a 1.125 radius at the start end. The flat across the bottom is 2" long and it ends with the same 1.125 radius. The error I get is the 367 cutter interference error but the radius I need to mill is 1.125 and the cutter is a 2" diameter so I should be ok? If I drop the cutter diameter in the offsets to 1" it works. Any thoughts? 2009 Haas VF7

Thanks Nathan

%

o07757

T02M6

(2 inch side cutter .25 thick)

G90G54G00X2.00Y-5.000

S200M3

G43H02Z-.7187M8

G42G01X0.0625Y-2.00D02F2.0

G1Y0.00

G2X.8131Y.287R1.125

G1X2.8131

G2X3.5637Y0.00R1.125

G1Y-2.00

G1X2.00Y-5.00

G1Z-1.21875

G1X.0625Y0.00

G2X.8131Y.287R1.125

G1X2.8131

G2X3.5637Y0.00R1.125

G1Y-4.00

G40X2.00Y-5.00

G00Z2.00M9

G53G49Z0M5

M30

%