Here is a nice drawing of a spider that can be used to hold the chuck jaws in compression while grinding. It does not take much time to make one from aluminum. I used this with a toolpost grinder some years ago and it worked very well.

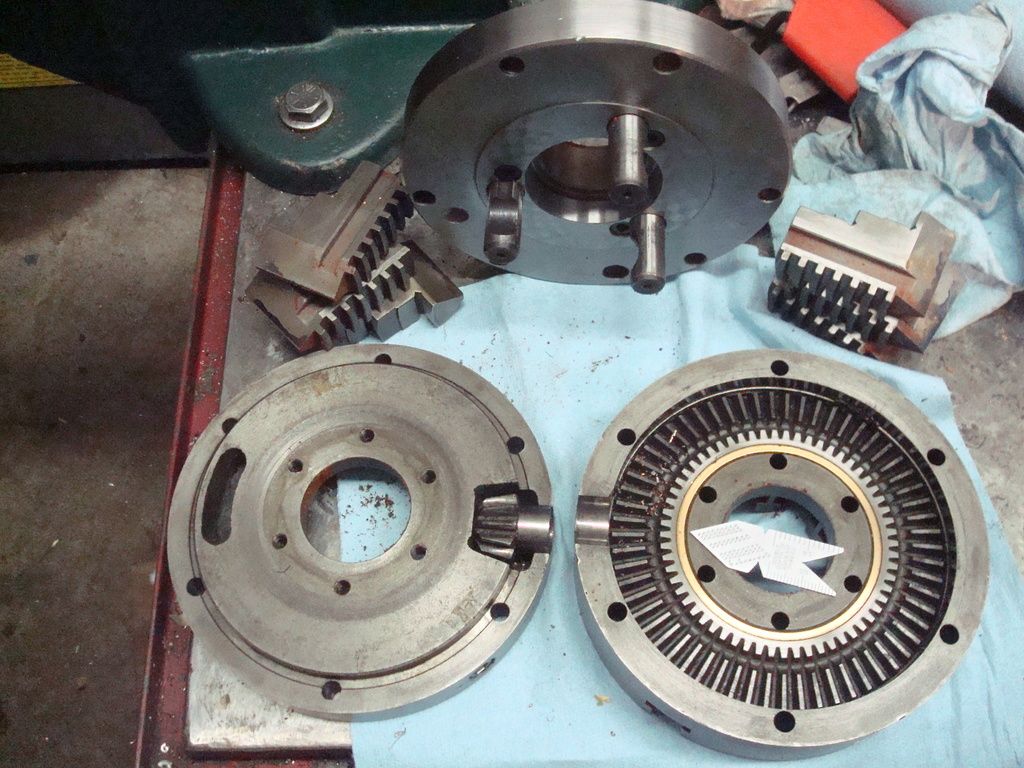

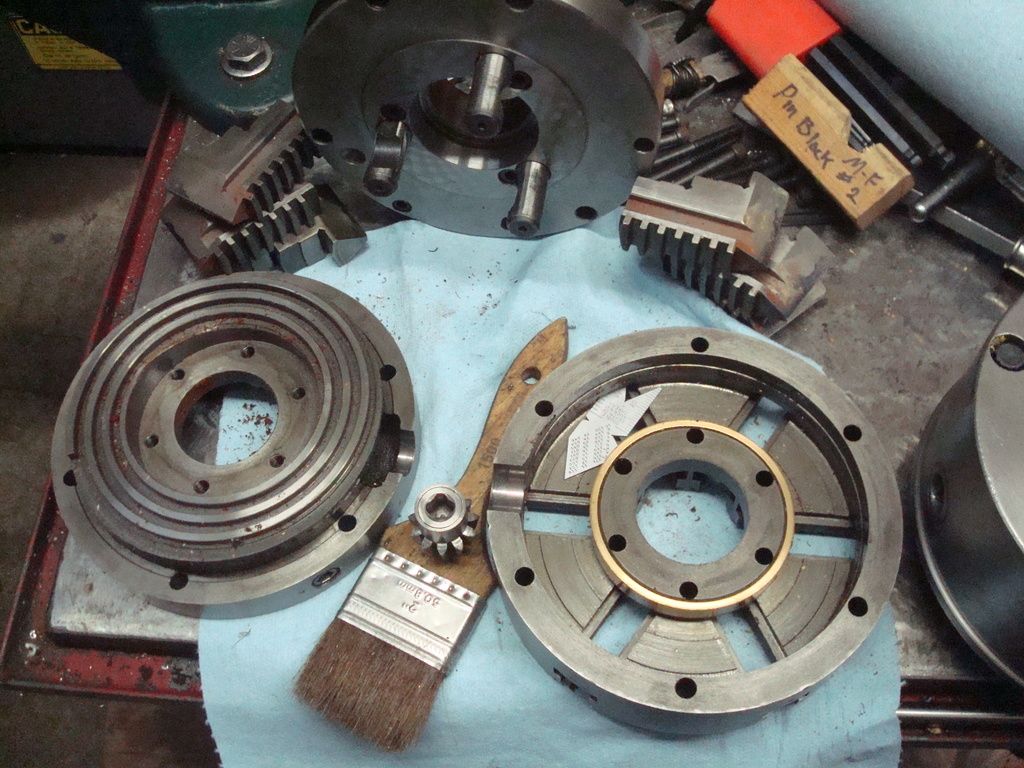

Chuck Jaw Truing Fixture

It can help you "somewhat", but there remains the challenge that much of the time a scroll operated chuck has uneven wear and/or "spot" distortion that is position sensitive.

Not much economic gain if this must be done over when changing diameter of the workpiece.

This is not just about THREE jaw scroll, BTW.

It also applies to 2-J, 6-J and 4-J "self centering" OR "combination" scroll operated chucks.

There are two much better ways to go about having a scroll-operated chuck that generates less hassle.

- first is the feature of being able to make minor centering alterations to the whole body. As-in set true, adjust true, tru-adjust - depending on what any given maker calls their version of it. Selecting this type is a VERY wise move on any new purchase. The feature can be, and has been, added to flat-back chucks that were not built for it at the factory, but not always easily.

- the other is two-piece jaws. All of my scroll operated chucks have these: 2-J, 3-J, and 6-J. The "top jaw" may be hardened or soft, and made of steel, aluminium, other metals, even NON metals. "Soft" ones can be readily drilled and bored without need of grinding.

Two-piece top jaws are also a wise upgrade when buying new. Conversions have been done. They are non-trivial work to plan and do, hence not ordinarily worth the effort vs the price of a new chuck.

A less intensive modification is to leave the OEM jaws in-place, drill and tap them so plates can be added. Not easy. Most jaws are hardened.

Not especially strong, either. Note that the "master" jaws of two-piece systems sit low in the body of the chuck so the overall height need not give the advantage of greater prying leverage to the work being gripped. The modification has no such advantage, and will also not have the strength of OEM ridges, dovetails, serrations, or "whatever".

Have a look at the ladner.fr catalog of top jaws for a hint at the "whatever". There are MANY ways two-piece jaws are done by many makers.

20CW

) while in compression as in clamping a piece of stock, but even then depending on how much wear is in the scroll or teeth, where you grind it will be only place it is accurate.

) while in compression as in clamping a piece of stock, but even then depending on how much wear is in the scroll or teeth, where you grind it will be only place it is accurate.