Strapping to pull broken iron castings together is a fix as old as the hills. It is well proven, and was used on everything and anything- freeze broken engine water jackets and water pumps being a common thing repaired with strapping. The beauty of a fracture with a clean break is that it has a "unique" joint. The irregularities in the fracture will mate up perfectly, in exact alignment, and will "key" the broken parts together so they do not move relative to each other. In fact, "fracture joints" were used in making steam engine flywheels, Jacobs drill chucks, and automotive connecting rod big-ends. Make up the capscrews which hold the bearing cap in place so the cap is rigidly held. Then, you can file the outer surface of the cap to dress it into a portion of a cylinder. Once you have done that, you are ready to fit the strap. My own method uses what I've learned from seeing this kind of repair, and my own experience. First, I make a shim out of soft copper. A piece of copper roofing flashing is fine, and anneal it so it is dead soft. Wrap the shim around the bearing cap. Next, cut a piece of steel flat bar for the actual strap. I'd use steel about 1/4" thick, and use something like A-36 (structural steel, hot rolled). My method of forming curved saddles and similar is to do them cold. You can weld 2 pieces of 1" diameter round bar to a piece of plate, the round bars being set parallel to each other with a gap of maybe 1 1/2" between them, or you can use a blacksmith's swage or swage block, or you can use damned near anything that has two solid edges with a gap between. The round bars produce less dinging or cutting into the outer circumference of the strap. Lay the piece of flat bar so it spans the gap in your swage, swage block, or home-made swage. Take a ball pein or cross pein hammer and start lightly hammering the portion of the flat bar that is bridging over the gap in the swage or your home made tool. As you start hammering, the flat bar will start to curve. You move the flat bar and keep hammering. More hammering tightens the radius of the curve. Use the bearing cap as your template to try the strap on.

Ultimately, you want the strap to be a good fit on the bearing cap, with the copper shim sandwiched in. Some filing on the inner circumference of the strap and dressing of the ends is to be expected. With very simple means and patience and a good eye, you will be surprised at how nicely this method works. Done it LOADS of times to make saddle plates, wrappers, and straps. If you get into hot-working the steel strap, the tendency is for the steel to "draw out" and wind up longer and thinner than what you started with. If you have an oxyacetylene torch with a small brazing tip, you can try some localized heating of areas to a red or orange-red heat if you need to tweak or bend them to make the fit happen.

By in large, cold forming should work for making the strap, with hot forming only needed at the end for the final fitting.

Once you are satisfied the strap is a good fit on the bearing shell, marry them together with some socket-head cap screws. I am guessing that 10-32 would be about all the big you want to go. I'd start with capscrews tying the strap to the bearing cap located at approximately 11:00 & 1:00. This leaves the 12:00 area free from tappings as it is the point of maximum stress in the bearing cap. Drill the strap with the tap drill size you are going to use, and use the strap as your drill jig. You might want to put a collar on the twist drill to make sure you do not overdrill into the bearing lands or worse. Drill the tap-drill sized holes in place using a hand-held drill. When you get the hole at 11:00 drilled to depth, open the hole thru the strap to the body drill size, and then counterbore for the socket head screw. Tap the hole in the cap and run in a socket head capscrew. Go to the opposite hole at 1:00 and do the same thing. Snug the cap screws. Work your way around the strap from the center to the flanges at the joint on the bearing cap. The capscrews get drawn up in a sequence, and you do not tighten them any more than needed. The soft copper will deform or "flow" to take up irregularities between the steel strap and the bearing cap casting. Makes for much better contact and avoids the strap and bearing cap only making contact at a few random points.

This is the old timer's method of fixing a broken casting where precision enters the equation. Any sort of welding or brazing processes would put heat into the casting and the post weld stress would distort the bearing cap. We are talking of parts that are line bored and finished to better than tenths of thousandths of an inch, so welding or brazing - while joining the broken casting pieces- would pull things way off. Very fine work is needed, and while you want to stabilize and join the broken parts, you need to do it in a manner which maintains the alignment of the broken pieces relative to each other, and does not add any stresses that force things out of line. The strapping has to be done carefully, and the last thing you want to do is try to force the strap to fit the bearing cap by using the cap as a forming block or similar. I've formed a lot of curved pieces using just the gap between the jaws of my heavy machinist vise of blacksmith leg vise, or with swages or home-made forming tools. The trick here is not to try to force the metal to bend around a duplicate "positive" or "male" form in the shape of the bearing cap. Using a simple swage and light hammer blows, you can move the metal a lot easier and smoother and make a nice curve with great control.

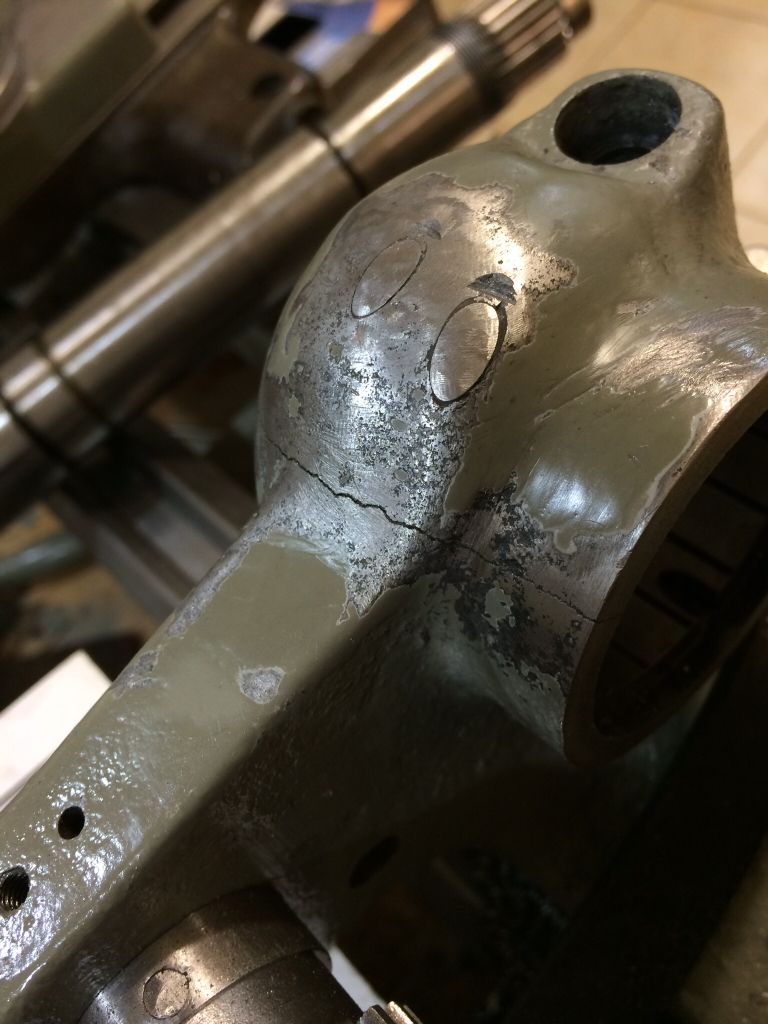

BTW: I erected a steam engine years ago which had a flywheel that was in two halves. The flywheel weight was 8 1/2 tons. The wheel was cast as a single piece, with cores in the rim of the wheel at about 3:00 & 9:00, along with flanges with cored bolt holes. The hub had similar cores, and bolting flanges. The rough casting of the wheel had been machined as a one piece casting, bored for the crankshaft and the keyway cut. It was then put on an arbor and outer diameter and rim faces machined. When that was done with, Skinner engine's shop used to "pop" the flywheels into two pieces by driving steel wedges. The fracture joint was unique to that wheel. The engine I re-erected was built in 1926, and I re-erected it overseas in 1981. We got the flywheel bottom half in the wheel pit in the foundation and then brought in the crankshaft, which also had the generator rotor on it. We set the bottom half of the flywheel on wood blocking so it was a little low, and put a hydraulic ram ("Porta Power") in the wheel pit to jack up the lower half of the rim when the time came. We cleaned the fracture joint on each half. We rigged in the top half and had it hanging on chainfalls. The halves were joined by about 1 3/4" diameter steel studbolts with fine pitch threads. These studs got heated to a "black heat" in a fire before installation. I put a little kerosene, a few drops, in the center of each fracture joint on the bottom half. We then let down the top half, still on the chainfalls, so it just rested on the crankshaft. We came up on the Porta Power so the bottom half just met the top half. We started putting in the studs in a mad rush as they had to go in hot. We ran the nuts down and slugged them up. When the studs cooled they drew the halves together in a real death grip. The proof as to the fit and tightness of the joint was seeing the kerosene and tiny air bubbles around the edge of fracture- the joint line was closed tight and just a wavy or jagged line. This was a fracture joint that utilized the inherent locking ability of a clean fracture. Your bearing cap is doing that same thing. Be extremely careful in how you handle and fit those pieces together as you need to keep the fracture surfaces "crisp and sharp" for the fracture joint to do its best work at locking the two pieces together. You mention seeing oil coming out of the crack in that bearing cap. That oil is your clue that the pieces are moving very slightly relative to each other. Machinery gives very subtle clues, and you keep your eyes, ears, and senses working and wits about you and you can read them. The cap sits on shims, and the shims can act as a sort of leaf spring, just a little resilience or "softness" in them. It's a catch 22 whether you tighten the cap up to come down hard on the shims, and risk opening the fracture joint. Some person in the lathe's past may well have gotten too frisky and sloppy in reassembling the cap onto that end of the headstock and pulled the capscrews unevenly, or messed up in the shimming so the cap was un-evenly shimmed and then tried to sock up on the capscrews to get things closed.

I've had a Southbend Heavy 10" lathe in my shop for almost 30 years. It has the bronze bearings. It was old and tired when I got it. I freshened up the bearings, and have done more work on that lathe than I can recall. Big jobs like wheel spaces for our tractor, and fine small parts and everything in between. The lathe is never entirely clean. Seems like when I clean it up and wipe it all down, I wind up machining cast iron or something to make a real mess of chips in a big hurry, and then another couple of jobs crowd in. For all the visible wear on that old lathe, it holds pretty tight accuracy and surprises me all these years later with what it can do- stuff like chasing a 6-32 or 4-40 thread, or making heavier parts seem all in its reach. Never underestimate an old Southbend lathe. Never underestimate your own mind and imagination at what you can do with that lathe, and how you can repair it. As I've come along in my life and career, I've learned that about 99.999% of the time "there is no single right way to do anything". If the end result is what is needed or meets the drawings and specifications, who cares how you got there ? As a kid learning to write, I had fine motor skill delays. I held my pencil my way and printed nicely enough. The teachers would grab my hand, "correct" me, and holler. As soon as they were off and away harassing some other hapless classmate, I'd write using my method. At home, I ate my meals holding my knife in my left hand, fork in the right and never put them down or changed hands. I was polite, asking to "please pass the peas" and saying "excuse me" if I needed to get up from the table or say something, so it was not like I was all hands and fingers in the food stuffing it into my craw. But, Mom would keep telling me the "correct" way to use a knife and fork. Hell, I was using TOOLS in Dad's shop and had tools of my own and was not getting maimed too badly. Dad was showing me tricks to move stuff with pinch bars, rope falls, or how to run pipe or nail up framing and each situation seemed just a little different. At the dinner table, I was not breaching any etiquette at the table that I could figure and I was not leaving anything on my plate, so what was the big deal ? At age 6, I realized: "There is no single right way...." In machine work, this is much the case. If you ask some "experts" they will tell you to go hunt up another used headstock, then you are into scraping it to fit your lathe's bed, then you are into checking the alignment of the tailstock to the headstock.... Another "expert" will tell you to part out the lathe and junk the headstock..... Here, most of us will tell you it is fixable, and probably a few different ideas about doing it.

Joe Michaels