Spyderedge

Titanium

- Joined

- Aug 28, 2013

- Location

- NY

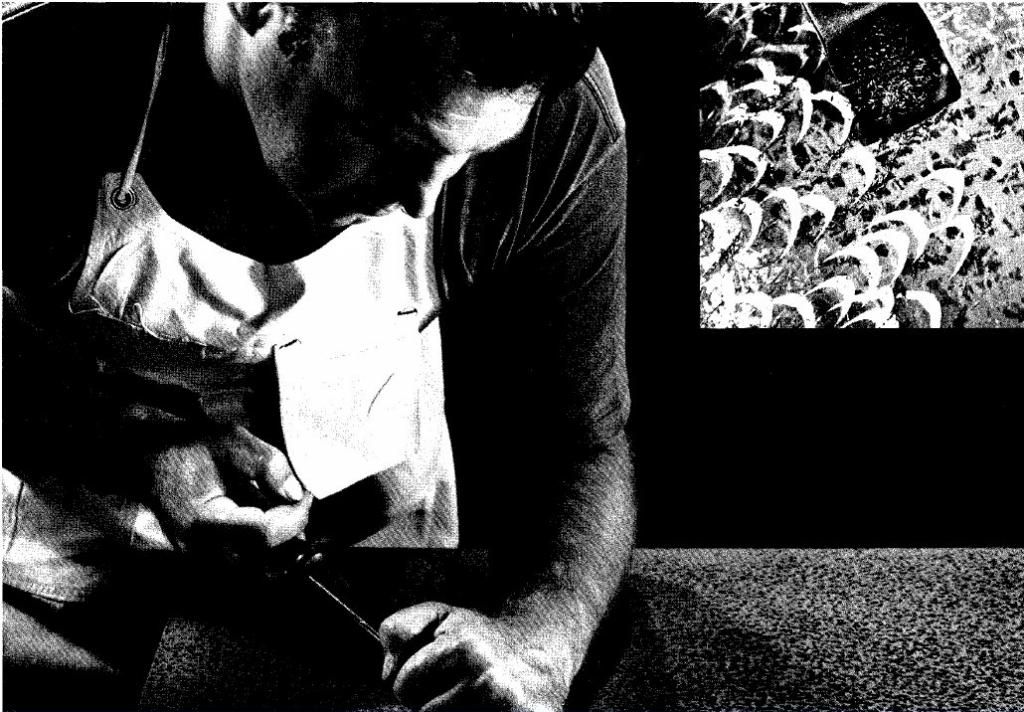

I'm reading through "The Art Of Hand Scraping" on the archives, and towards the beginning he mentions the practice of hook scraping and how precise it can be compared to other scraping techniques (Writer claims up to a 50 millionths surface deviation.)

Now since this is a text, there are no pictures. Does anybody have pictures of a hook scraped finish, somebody practicing hook scraping, or better yet all the pictures in the book, or a text with pictures of the book?

I don't plan on learning hook scraping, as I am still learning push and pull scraping, but while I'm reading the book I might as well understand what I'm reading.

Thanks, all!

Now since this is a text, there are no pictures. Does anybody have pictures of a hook scraped finish, somebody practicing hook scraping, or better yet all the pictures in the book, or a text with pictures of the book?

I don't plan on learning hook scraping, as I am still learning push and pull scraping, but while I'm reading the book I might as well understand what I'm reading.

Thanks, all!