Lurk

Cast Iron

- Joined

- Feb 10, 2014

- Location

- Peak District UK

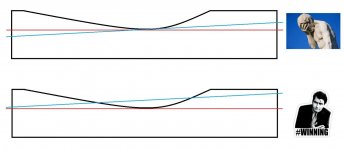

I have been searching these threads and YouTube to try to find out the thought processes to determine the sequences for scraping in for example a lathe bed with two inverted V's and two flats. There is plenty of information and video on beds with flat ways and lots of cross slides dovetails etc

So far I have not found anything which describes the sequence once the 'mapping out' for wear has been completed on anything other than flat bed ways.

I fully appreciate that such information may be hidden in this forum somewhere - but Ive not come across it yet and Ive been reading it for a few years now.

A little surprised as its something every project has to go through at the start.

Any thoughts, links to videos etc much appreciated

Thanks

Mat

PS - am interested to see if I get any replies - please do let me know if you would like your replies included / excluded in any future work I undertake on YT - I will try and include as many as possible ;-)

PPS - Happy New Year to everyone :-)

So far I have not found anything which describes the sequence once the 'mapping out' for wear has been completed on anything other than flat bed ways.

I fully appreciate that such information may be hidden in this forum somewhere - but Ive not come across it yet and Ive been reading it for a few years now.

A little surprised as its something every project has to go through at the start.

Any thoughts, links to videos etc much appreciated

Thanks

Mat

PS - am interested to see if I get any replies - please do let me know if you would like your replies included / excluded in any future work I undertake on YT - I will try and include as many as possible ;-)

PPS - Happy New Year to everyone :-)