trafficbikes

Plastic

- Joined

- Jan 21, 2009

- Location

- New York

Hey all-

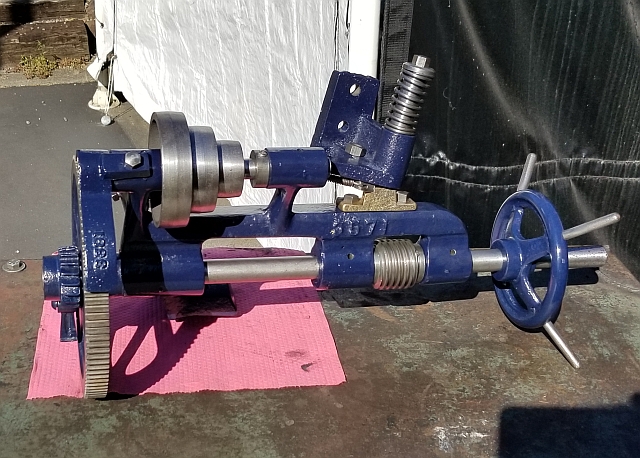

I'm in the process of fully rebuilding a Walker Turner 900 drill press. The machine's castings were all chipping and also I got a new (old) belt cover that was completely unpainted, so I pulled the whole thing apart and planned to strip and repaint.

I chipped off most of the paint (there were multiple layers) with a scraper. In most areas it came off in chips about .75" across, and underneath is a combination of raw iron and some of what I assumed to be the original paint. I sanded with 60 grit, scrubbed everything with degreaser, rinsed it with water, and dried it out. The result was not paint or rust free, but it was free of big chunks and felt like it had been pretty well prepped.

I checked the paint that was left with rubbing alcohol, and it seemed to come off easily - so I assumed that it was water based. I then brushed on an acrylic primer - a Sherwin Williams Pro-Cryl Industrial. I don't have much experience painting cast iron, but it seemed to me almost immediately that the coverage was blotchy - almost like I was painting over an oil base. Then, over the next hour or two as the primer dried, little rust spots started appearing almost everywhere.

I have an oil topcoat planned, but now I'm worried. Were the remnants of the original paint actually an oil coat? And did I totally mess up by not using PickleX under the primer? I'm putting a fair amount of work into this machine, and don't want to end up with flaking paint again. Any suggestions appreciated!

Spencer Wright

(Note: Sorry for the weirdly rotated photos!)

I'm in the process of fully rebuilding a Walker Turner 900 drill press. The machine's castings were all chipping and also I got a new (old) belt cover that was completely unpainted, so I pulled the whole thing apart and planned to strip and repaint.

I chipped off most of the paint (there were multiple layers) with a scraper. In most areas it came off in chips about .75" across, and underneath is a combination of raw iron and some of what I assumed to be the original paint. I sanded with 60 grit, scrubbed everything with degreaser, rinsed it with water, and dried it out. The result was not paint or rust free, but it was free of big chunks and felt like it had been pretty well prepped.

I checked the paint that was left with rubbing alcohol, and it seemed to come off easily - so I assumed that it was water based. I then brushed on an acrylic primer - a Sherwin Williams Pro-Cryl Industrial. I don't have much experience painting cast iron, but it seemed to me almost immediately that the coverage was blotchy - almost like I was painting over an oil base. Then, over the next hour or two as the primer dried, little rust spots started appearing almost everywhere.

I have an oil topcoat planned, but now I'm worried. Were the remnants of the original paint actually an oil coat? And did I totally mess up by not using PickleX under the primer? I'm putting a fair amount of work into this machine, and don't want to end up with flaking paint again. Any suggestions appreciated!

Spencer Wright

(Note: Sorry for the weirdly rotated photos!)