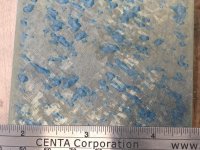

I am a new scraper but I have been at a bit. My Biax is developing the scratches in the pictures. They appear on the return stroke as well as the forward stroke of the scrape. Carbide blades sharpened with 3000 grit diamond. This is driving me crazy and didn't occur on previous project. Any ideas as to what is causing this? Thanks.

Guy goes to the urologist with a complaint. So the doc says: "Let's take a look at it, get this gown on, and begin". Guy goes behind the divider, starts changing, looks out from behind the divider, and asks for a hanger, doc finds a hanger hands him the hanger, A few seconds later he asks for comb, doc says he does not have a comb, some time passes he asks for a lint brush, doc is a bit annoyed and tells him does not have one, a few seconds later gay ask the doc if there is a place where he can hang his clothes, doc is a bit irritated now, but keeps his cool, tells him to hang it on the divider....

This point the guy comes out sits down on the examining table and the doc collects his cool.

"So please describe your problem". The guy, "I rather show it and see if you can see it" He opens his gown and stands in from of the doc. Doc is looking at it and says: " I see nothing wrong" The guy insists that he looks again and insists that the problem is right there and very visible. The Doc stars at the guy's privates and says: "Nope it all looks normal to me, but indulge me and describe the "problem"". To which the guy: "Well I am disappointed that you do not see it, but it is most obvious that the left one is quite a bit lower than the right one". At this point, the doc is in disbelief, but being a cool professional, explains that it is normal, everybody is like that, and so on, but just out of curiosity he asks: "Why do you think it is a problem?"

"Well doc you see, I do not know how you can live with such an untidy mess."

Besides the joke, you are being a bit hard on yourself

. I think you are pressing down too hard so the Biax does not have time to lift the blade from the surface, and I think you also have the rake on the blade wrong, it looks like chatter on the forward stroke, but it might be just a bad photo. Run your nail over the edge of your blade, if it catches at all you have smal nicks. Please describe why you think the return scratches are a problem?

dee

;-D