marka12161

Stainless

- Joined

- Dec 23, 2016

- Location

- Oswego, NY USA

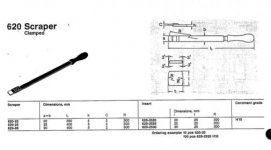

I need to get myself set up to do some hand scraping. Mostly lathe cross slide flats and in a few cases some very tight areas like in the cross slide dovetails, compound rest dovetails etc. I've told myself i'll need a couple of different size blades. I've found plenty of insert blades on ebay but these all look a bit too beefy to get into the really tight spaces. I realize i may need to braze the carbide to the handle which isn't a big deal for me. Can anyone recommend good sources for these blades?

Also, while i'm at it, what's the consensus on the best stock to build the scraper shank out of? Is it as simple as hot rolled bar stock?

Mark

Also, while i'm at it, what's the consensus on the best stock to build the scraper shank out of? Is it as simple as hot rolled bar stock?

Mark