Halcohead

Stainless

- Joined

- Apr 10, 2005

- Location

- Bay Area, Ca

The time has come to sell off some of the less-used machinery in the shop. Things are too crowded.

For sale Monarch Series 60 16x54 lathe, made January 1949, serial # 32039.

The machine is running and can be inspected under power. 3-phase of course. I believe it's 220, but may be 440 (it's labelled, but been a while since the machine has been used).

18.5" actual swing, 54" between centers. D series spindle nose (D1-6", IIRC).

Taper attachment

16 speeds, 12-472 rpm

Includes 3-jaw chuck with reversible top-jaws, two steady rests, 4-position toolpost, live center, two micrometer stops.

The machine has the typical rough paint but no known mechanical issues. It has been idle for the past 4 years, but now occupying space better suited to a CNC lathe. I'm in no huge rush to see it go but certainly don't want to see it get scrapped.

$2000 for the lathe. I can load onto any trailer shorter than 20 feet with the bridge crane. A longer trailer would require a forklift. I estimate machine weight of 6000-8000 lbs.

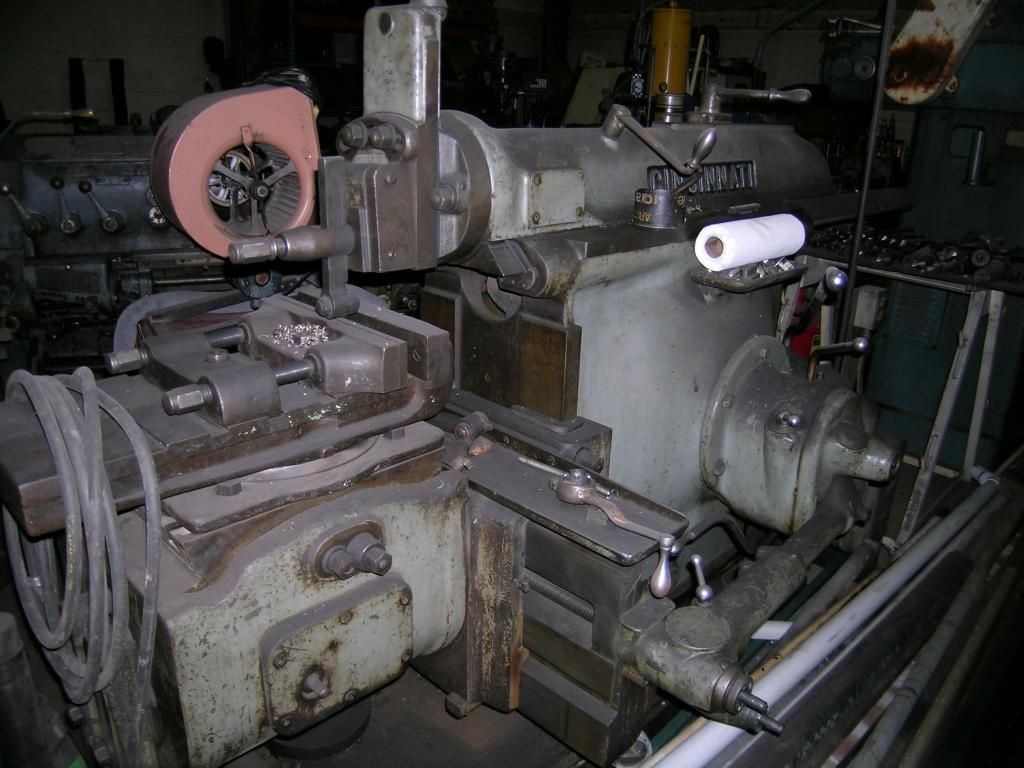

There is also a Cincinnati horizontal mill with an adapter for a bridgeport vertical head (I can also throw in a taiwanese bridgeport knockoff head in need of a rebuild), a Van Norman #16 (14x60 table) horizontal/vertical mill, a Cincinnati 24" universal shaper, and a Reed-Prentice 18x54(?) toolroom lathe for sale. If there is any interest in any of these machines, let me know and I'll post some photos and specs. All machines (possibly excepting the Cincinnati mill) can be tested under power.

My apologies for the poor photos.

Tooling, including bed bracket for taper attachment:

For sale Monarch Series 60 16x54 lathe, made January 1949, serial # 32039.

The machine is running and can be inspected under power. 3-phase of course. I believe it's 220, but may be 440 (it's labelled, but been a while since the machine has been used).

18.5" actual swing, 54" between centers. D series spindle nose (D1-6", IIRC).

Taper attachment

16 speeds, 12-472 rpm

Includes 3-jaw chuck with reversible top-jaws, two steady rests, 4-position toolpost, live center, two micrometer stops.

The machine has the typical rough paint but no known mechanical issues. It has been idle for the past 4 years, but now occupying space better suited to a CNC lathe. I'm in no huge rush to see it go but certainly don't want to see it get scrapped.

$2000 for the lathe. I can load onto any trailer shorter than 20 feet with the bridge crane. A longer trailer would require a forklift. I estimate machine weight of 6000-8000 lbs.

There is also a Cincinnati horizontal mill with an adapter for a bridgeport vertical head (I can also throw in a taiwanese bridgeport knockoff head in need of a rebuild), a Van Norman #16 (14x60 table) horizontal/vertical mill, a Cincinnati 24" universal shaper, and a Reed-Prentice 18x54(?) toolroom lathe for sale. If there is any interest in any of these machines, let me know and I'll post some photos and specs. All machines (possibly excepting the Cincinnati mill) can be tested under power.

My apologies for the poor photos.

Tooling, including bed bracket for taper attachment: