I have a part that takes 6061 tubing with a .002" ID tolerance. One is 1.375" ID and the other is 1.000" ID. Both are .125 wall. Lengths are 8" on small tube and up to 11" on 1.375 tube.

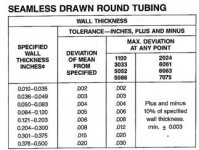

To avoid having to bore the ID I'd like to get some extruded to size but I'm not sure the tolerance can be kept.

Does anyone have a source they've used for custom extrusions? Or somewhere that may stock this since it's a pretty common size?

Right now I'm stuck buying structural tubing from Alro here in Charlotte and boring to size, with I'm assuming, a big carbide boring bar. I think chatter may be a problem.

To avoid having to bore the ID I'd like to get some extruded to size but I'm not sure the tolerance can be kept.

Does anyone have a source they've used for custom extrusions? Or somewhere that may stock this since it's a pretty common size?

Right now I'm stuck buying structural tubing from Alro here in Charlotte and boring to size, with I'm assuming, a big carbide boring bar. I think chatter may be a problem.