cmdevans

Aluminum

- Joined

- Jan 5, 2011

- Location

- south of indy, IN, USA

Repairing a 1970s Harrington hoist. Mostly electrical issues left to sort out, the mechanicals have been sorted out.

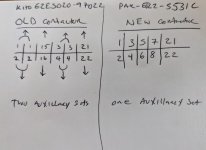

The current issue is the contactors for the controls. I got new contactors from Harrington via MSC, purportedly direct replacements, but the new ones have one auxiliary set of terminals(21/22), whereas the old ones have two auxiliary sets (15/16 and 21/22) (21/22 set are on sides of contactor housing)

Do I need a different contactor, an add on auxiliary contactor unit, or is there a way to wire this properly as is? I've been unable to get ahold of Harrington directly so far,and would love to get this crane back in service sometime soon.

I've got diagrams and pictures, trying to get them uploaded at the moment.

The current issue is the contactors for the controls. I got new contactors from Harrington via MSC, purportedly direct replacements, but the new ones have one auxiliary set of terminals(21/22), whereas the old ones have two auxiliary sets (15/16 and 21/22) (21/22 set are on sides of contactor housing)

Do I need a different contactor, an add on auxiliary contactor unit, or is there a way to wire this properly as is? I've been unable to get ahold of Harrington directly so far,and would love to get this crane back in service sometime soon.

I've got diagrams and pictures, trying to get them uploaded at the moment.