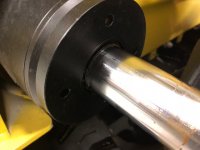

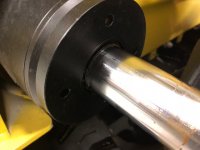

probably can't tell it in photo below but wiper (dust) seal is cracked pretty bad. Could that alone account for oil pretty much soaking one tire and leaking somewhat on the other... or more likely internal seals kaput as well ? Amazes me that prior to yesterday neither cylinder leaked a drop but all of a sudden they *both* start leaking. (prior to leaks I didn't lift/tilt anywhere near the capacity of the lift truck)

Also any helpful tidbits on replacing the wiper seal ? i.e. can I loosen the clevis thread clamp and simply unscrew the ram from the clevis in place ?

Also any helpful tidbits on replacing the wiper seal ? i.e. can I loosen the clevis thread clamp and simply unscrew the ram from the clevis in place ?