This is the super major league

Very interesting industry lesson rhb. I wonder how many rig owners would face up to a $2M/day crane barge and crew vs how many would dissolve, abandon the rig and change names. Even with the big exploration numbers quoted, no return on an old rig that needs that big of a crane to demob.

When Rita and Katrina trashed a large number of platforms, a company made a very low cost (under $1 million IIRC) vessel out of a some barges that could lift a platform off the seafloor and move it to deepwater for disposal.

The companies which rent cranes like this are called "supermajors", Exxon, BP, Chevron, Shell. Not sure if Total ranks as a supermajor. Hard to say about CNOOC and the other Chinese companies.

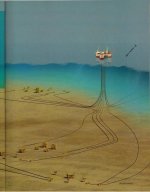

You don't need this lift capacity to decommission a platform, you need it to place an entire topsides package on something like a spar. I can't find the brochure about Perdido, but I'm pretty sure Shell did a 10-12,000 ton lift to place the topsides on the Perdido spar. I think McDermott did the lift using a pair of cranes.

If you're spending several billion dollars developing a field, $5-10 million for the crane rental is pocket change. And if you're spending that on crane rental it's because it will save a few million.

About the time I started working for Unocal, they signed a contract to lease a drillship for 5 years at a day rate of $425,000/day. That was a "take or pay" contract. It was insane as they only had three deepwater prospects. The CEO was a former refinery engineer who literally "bet the company" on succeeding when the chances of failure were 10:1. When he became CEO his first action was to sell off downstream (marketing and refining) because it was a "lousy business". I attended a small meeting with him and spoke with him afterwards. He had absolutely no comprehension of statistics and risk management. In the meeting he said he wanted to generate a 15% ROI like they did in Silicon Valley. This was in 2000. Historically oil companies have never done much better than 5-8% ROI. Better than utilities, but not as good as manufacturing. But a well run oil company is a very reliable investment.

The amount of money required for a deepwater development is so large that *no* company can afford to do it alone. Not even Exxon can afford to drill $225 million wells at 100% ownership. When Blackbeard was abandoned at 32,000 ft, 3000 ft short of the objective because poor pore pressure prediction work had run the well out of hole, Exxon wanted to try again. But the partners said no. Blackbeard is the most expensive well I know of, though I worked on plenty which were in the $50-150 million range. Blackbeard was in 20 ft of water, but it was very deep and the pressures were very high.

Slippery Joe and Fast Eddie, Inc. are not players in this game. In the US they would not even be able to buy an offshore field. They would not have the financial capacity to relieve the seller of liability. Neither the seller nor the government would agree to it.

My biggest concern is the unemployment that is about to hit the people who build all this stuff. No one is looking for $70/bbl oil when they can get it for $6 in West Texas. Once the the contracts signed when oil was over $70/bbl are completed lots of machinists, welders and other very high skill craftsmen will be out of work.

My friends and I worked upstream. We were let go years ago. We're getting close to the downstream fabrication people getting let go. There is an 8-10 year lag between finding oil and producing it in deepwater. That's how long it takes to design and manufacture the equipment required. It's a few months onshore.

An addendum:

That crane was not built on speculation. They had over 85% of the cost of the crane covered by contracts with AAA+ companies who wanted it and were willing and able to pay if they did not use their share of crane time. The Unocal drillship was built and named "Discoverer Spirit" because the Spirit subsidiary of Unocal signed a contract that paid for building it. There were periods of time when you could make $50-100,000/day renting it out when you didn't need it. There were other times when you lost $425,00/day for lack of work.