I have about a week of downtime between jobs on my 1989 Mazak QT8 and would like to replace the hydraulic seals on the turret shaft assembly during this time. I have a steady hydraulic fluid drip on the turret side that flows from between the turret housing and the rotating assembly, so I am assuming these seals are the culprit. I have pulled the rotating turret disk and curvic couplings off before for alignment but have never gone any deeper into the hydraulic piston and motor assembly. After looking through the parts diagrams it seems fairly straightforward, but I wanted to double check a couple things and see if any PM members have advice to make the process go smoothly.

Questions:

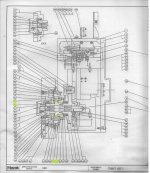

I know these are basic questions for anyone who has done this job before, but the single drawing of the turret innards only helps so much for someone who hasn't done it before. Since the machine needs to be making parts again soon, I'm trying to plan ahead so I don't get any surprises during the maintenance. I would really appreciate anyone with the experience on a similar machine to let me know if I am on track here, thanks!

Questions:

- It looks like I need to replace a total of 4 O-RIngs to restore the seal. These are parts 74, 78, 79, and 83 highlighted in the diagram attached below. Is there anything else as far as seals or wear items that should be replaced while I am in there?

- It seems like this can all be done from the turret/shaft side once the rotating assembly is removed. Is there any need to enter from the backside of the turret or remove the gearmotor assembly?

- Since all the JIS sizes of these O-Rings are listed in the manual, I was just going to order the necessary sizes in 70 durometer Buna-N material to avoid the Mazak mark-up. Is there any reason to order a different material/durometer or to order the OEM Mazak parts instead?

- When I remove the rotating part of the turret, I have unclamped it while the machine was running. I'm assuming the procedure to access the seals will be to unclamp and remove the turret while the machine is on, then turn the machine off to depressurize the hydraulic system, and finally disassemble the piston and replace seals. Is there anything else, process or preparation, that I am missing? Is there any adjustment to the hydraulic piston/motor assembly that must be done upon reassembly?

I know these are basic questions for anyone who has done this job before, but the single drawing of the turret innards only helps so much for someone who hasn't done it before. Since the machine needs to be making parts again soon, I'm trying to plan ahead so I don't get any surprises during the maintenance. I would really appreciate anyone with the experience on a similar machine to let me know if I am on track here, thanks!