How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

QT28 with T2 control spindle drive issues

- Thread starter mada87

- Start date

- Replies 17

- Views 6,600

hitandmiss

Titanium

- Joined

- Jul 31, 2010

- Location

- Rochester, NY USA

Posting an accurate wording of the alarm is a good place to start.

"Something" in the wording will keep most people away.

"Something" in the wording will keep most people away.

Posting an accurate wording of the alarm is a good place to start.

"Something" in the wording will keep most people away.

Thanks for the tip. Please see my update below. I tried to edit the original post but couldn't figure out how.

Hi,

I have a QT28 with T2 control. It will run the spindle at 1000rpm all day long but if we go much faster the spindle drive will fault out giving an ALO 32 alarm (over voltage is what Mits told me on the phone but when I looked it up I found over current instead). It is a FR-SF drive. Any thoughts on what the issue is?

Thanks

hitandmiss

Titanium

- Joined

- Jul 31, 2010

- Location

- Rochester, NY USA

Try running the spindle at 10 RPM.

Does it turn smoothly, or pause (may even turn backward) then jump a little?

You may need to look at the motor pulley to see that the jump happens at the same place in the motor rotation.

If jumpy, the power supply at the top of the FR-SF that has a bunch of voltages that it provides.

There is probably 1 or more that are low or missing.

Then there will be sections of the 3 phase power to the motor that are missing.

As the speed increases, the current draw on the phase after the missing section will tend to have an overload, if severe enough, the overload can take out the associated power transistor module.

Bill

Does it turn smoothly, or pause (may even turn backward) then jump a little?

You may need to look at the motor pulley to see that the jump happens at the same place in the motor rotation.

If jumpy, the power supply at the top of the FR-SF that has a bunch of voltages that it provides.

There is probably 1 or more that are low or missing.

Then there will be sections of the 3 phase power to the motor that are missing.

As the speed increases, the current draw on the phase after the missing section will tend to have an overload, if severe enough, the overload can take out the associated power transistor module.

Bill

Try running the spindle at 10 RPM.

Does it turn smoothly, or pause (may even turn backward) then jump a little?

You may need to look at the motor pulley to see that the jump happens at the same place in the motor rotation.

If jumpy, the power supply at the top of the FR-SF that has a bunch of voltages that it provides.

There is probably 1 or more that are low or missing.

Then there will be sections of the 3 phase power to the motor that are missing.

As the speed increases, the current draw on the phase after the missing section will tend to have an overload, if severe enough, the overload can take out the associated power transistor module.

Bill

Just tried and at least to the naked eye it does not appear to jump at all, seems to run pretty smooth

I am now finding that I can run it up slowly to 1500 rpm in hand mode and if I stop the spindle it then will fault and give me an ALO 33 over voltage. At the moment I'm not sure that I can reproduce an ALO 32 alarm. We did still run all day making parts just limited to 1000 rpm (I'm working on it after hours now).

hitandmiss

Titanium

- Joined

- Jul 31, 2010

- Location

- Rochester, NY USA

Check the 3 phase power to the bottom of the FR-SF. Phase to phase and phase to ground, 6 checks.

Line voltage may be a little high.

When does it fault out above 1000 RPM?

Picking up speed? slowing down? or as soon as it arrives at speed? Or while cutting.

Are you using constant RPM or Constant surface speed?

Line voltage may be a little high.

When does it fault out above 1000 RPM?

Picking up speed? slowing down? or as soon as it arrives at speed? Or while cutting.

Are you using constant RPM or Constant surface speed?

Check the 3 phase power to the bottom of the FR-SF. Phase to phase and phase to ground, 6 checks.

Line voltage may be a little high.

When does it fault out above 1000 RPM?

Picking up speed? slowing down? or as soon as it arrives at speed? Or while cutting.

Are you using constant RPM or Constant surface speed?

I will check the phases.

At least when I have seen the issue happen it is when it is slowing down (going from 1400rpm or greater to 0).

I'm not sure if it does it while cutting, it has happened while running parts but I have never been watching it at that point in able to tell what the machine was actually doing then and my operator wasn't sure either.

I don't run the lathe myself so I am not sure if he uses constant rpm, surface speed or a combination.

Note I am currently attempting to adjust the accel/decal time constant but given my specific machine control/drive combination (T2 control with an FR-SF drive, most T2's had FR-SEs) can't seem to find the info to get it changed. The parameter isn't available on the drive directly (unless I am missing something in the manual) so it appears to be stored in the NC parameters but I can't find it and Mazak seemed stumped, going to try them again later today.

hitandmiss

Titanium

- Joined

- Jul 31, 2010

- Location

- Rochester, NY USA

I have the FR-SF service manual BNP-A 0801-19-D-E

File size is over 15 MB.

The T2 control is not bus linked to the drive, so all the drive parameters are set on the drive.

#33 is for accel.

#5E is for speed change cushion

#5F is also associated.

I will try to send you a copy via email, if needed.

Bill

File size is over 15 MB.

The T2 control is not bus linked to the drive, so all the drive parameters are set on the drive.

#33 is for accel.

#5E is for speed change cushion

#5F is also associated.

I will try to send you a copy via email, if needed.

Bill

Alright, so I am finally getting back around to this issue, we have only needed to use the lathe intermittingly and just used it at the slower rpm without issue. Well this morning the machine would not come up ready because the drive now has a ALO 24 alarm (breaker trip). I have gone thru Mitsubishi Alarm 24 troubleshooting (USA-E99991-042-*), it does not appear to be the motor or sf-ca card.

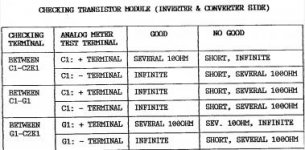

I have also gone thru the first part of the FR-SF Checking transistor module document. It notes that a analog multimeter should be used, (using my digital one switching positive and negative leads did not change the measurements like the document showed, so I bought an analog one). I do now get different readings switching the leads but am not sure if I am checking/understanding it correctly. Currently it is looking to me like all of the transistors on the right side of the drive are reading bad. Does it seem likely that all would go bad at the same time?

Thanks

Note I previously tried to change the accel and decal drive parameters, since this is a T2 they aren't supposed to be saved in the control, but when I tried to change them on the drive itself they appear to be hidden (like they are bus linked). Talking with Mits and Mazak got me nowhere on this as it appears that an FR-SF paired with a T2 is not very common.

View attachment 277523

I have also gone thru the first part of the FR-SF Checking transistor module document. It notes that a analog multimeter should be used, (using my digital one switching positive and negative leads did not change the measurements like the document showed, so I bought an analog one). I do now get different readings switching the leads but am not sure if I am checking/understanding it correctly. Currently it is looking to me like all of the transistors on the right side of the drive are reading bad. Does it seem likely that all would go bad at the same time?

Thanks

Note I previously tried to change the accel and decal drive parameters, since this is a T2 they aren't supposed to be saved in the control, but when I tried to change them on the drive itself they appear to be hidden (like they are bus linked). Talking with Mits and Mazak got me nowhere on this as it appears that an FR-SF paired with a T2 is not very common.

View attachment 277523

Attachments

Alright, so I am finally getting back around to this issue, we have only needed to use the lathe intermittingly and just used it at the slower rpm without issue. Well this morning the machine would not come up ready because the drive now has a ALO 24 alarm (breaker trip). I have gone thru Mitsubishi Alarm 24 troubleshooting (USA-E99991-042-*), it does not appear to be the motor or sf-ca card.

I have also gone thru the first part of the FR-SF Checking transistor module document. It notes that a analog multimeter should be used, (using my digital one switching positive and negative leads did not change the measurements like the document showed, so I bought an analog one). I do now get different readings switching the leads but am not sure if I am checking/understanding it correctly. Currently it is looking to me like all of the transistors on the right side of the drive are reading bad. Does it seem likely that all would go bad at the same time?

Thanks

Note I previously tried to change the accel and decal drive parameters, since this is a T2 they aren't supposed to be saved in the control, but when I tried to change them on the drive itself they appear to be hidden (like they are bus linked). Talking with Mits and Mazak got me nowhere on this as it appears that an FR-SF paired with a T2 is not very common.

View attachment 277523

Well I am either doing something wrong or this Mits document is wrong. I got replacement transistors and according to the Mits document they are all bad as well. Once I found this I went and checked a running machine and all of those transistors "check as bad" as well.

Well I am either doing something wrong or this Mits document is wrong. I got replacement transistors and according to the Mits document they are all bad as well. Once I found this I went and checked a running machine and all of those transistors "check as bad" as well.

So the crisis has been averted but the issue isn't completely fixed. I ended up checking the SF-PW even though the card was powered up it appeared that some of the voltages were off. I replaced it with a spare SF-PW30 that I had and the lathe is back running, but it appears that I am still limited on rpm to about 1500rpm, if I go higher I risk getting a 33 alarm spindle overvoltage, which appears to happen most often when the spindle is slowing down. I think that I have gotten a 32 as well (spindle overcurrent) but I can't reproduce it right now.

Still can't seem to figure out how to check if a transistor is good or bad, so if anyone can shed light that would be appreciated.

Also wondering if anyone would know how to get parameters #33, #5E, and #5F to show up on the drive, when I toggle thru the parameters they restart back to the beginning before getting to these.

benganboll

Hot Rolled

- Joined

- Feb 23, 2015

- Location

- Sweden Östersund

Replace all capacitors in both the power supply and the drive.

Replace all capacitors in both the power supply and the drive.

I will get some of the big capacitors coming for the drive, for the power supply is it worth fixing it?

I have 4 SF-PW's (standard 10 watt version) that have been fried in different machines over the last 6 months, I put a SF-PW30 (updated 30 watt version) in the 2 machines with issues and haven't fried any since. I am still unsure if it was just due to old/tired SF-PWs or if there is something in the machine that is drawing more current and taking out the power supply.

hitandmiss

Titanium

- Joined

- Jul 31, 2010

- Location

- Rochester, NY USA

Also wondering if anyone would know how to get parameters #33, #5E, and #5F to show up on the drive, when I toggle thru the parameters they restart back to the beginning before getting to these.

Did you ever get to the proper manual? BNP-A 0801-19-D-E

Seems that there are many parameter screens see pg 30 of above doc.

Bill

Did you ever get to the proper manual? BNP-A 0801-19-D-E

Seems that there are many parameter screens see pg 30 of above doc.

Bill

I have found manual BNP-A 0801-18 for a FR-SF drive on Mits website but not the document number that you are referencing. Do you have a copy that you could PM me?

hitandmiss

Titanium

- Joined

- Jul 31, 2010

- Location

- Rochester, NY USA

The file I have is over 15 Meg. I can't PM a file that size.

PM me your email address and I will try that way.

Bill

PM me your email address and I will try that way.

Bill

The file I have is over 15 Meg. I can't PM a file that size.

PM me your email address and I will try that way.

Bill

PM sent, thanks!

Similar threads

- Replies

- 2

- Views

- 165

- Replies

- 0

- Views

- 148

- Replies

- 3

- Views

- 469