Mar71n

Plastic

- Joined

- Feb 10, 2012

- Location

- England in the midlands

New here so Hello.

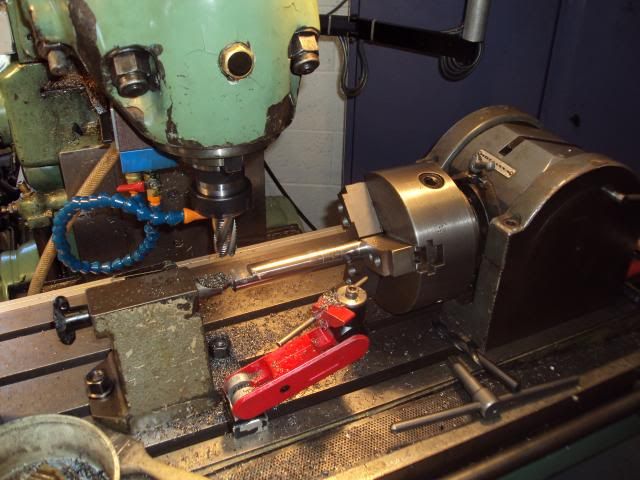

Few pictures of my kit.

I have solidworks as CAD & EdgeCam as CAM & do a wide range of work from machined for billet parts, castings supplied & machined & press tools & low volume press work. I have been in business for 23 years in March but this is the most difficult time I have worked through.

Just produced these.

Thats all for now

Few pictures of my kit.

I have solidworks as CAD & EdgeCam as CAM & do a wide range of work from machined for billet parts, castings supplied & machined & press tools & low volume press work. I have been in business for 23 years in March but this is the most difficult time I have worked through.

Just produced these.

Thats all for now

[/URL

[/URL