Hello,

Need expert opinion...

I have a Mitutoyo Bright BRT910 with a Renishaw PH9 probe.

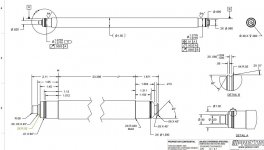

I need to measure datum A bearing journal to opposing datum B bearing journal that are spanning approximately 24.4” from each center point of journal, the bearing journals are approximately 1.10" in length.

The dwg has geometric control for True Position .01, Parallel .003, Datum B reporting to Datum A.

Q: is the CMM hardware/CMM manager software capable of making accurate measurements per the geometric callouts on the attached dwg?

It looks to me that there could be too much error being that the bearing journals are so far apart.

Regards,

KincadeM

Need expert opinion...

I have a Mitutoyo Bright BRT910 with a Renishaw PH9 probe.

I need to measure datum A bearing journal to opposing datum B bearing journal that are spanning approximately 24.4” from each center point of journal, the bearing journals are approximately 1.10" in length.

The dwg has geometric control for True Position .01, Parallel .003, Datum B reporting to Datum A.

Q: is the CMM hardware/CMM manager software capable of making accurate measurements per the geometric callouts on the attached dwg?

It looks to me that there could be too much error being that the bearing journals are so far apart.

Regards,

KincadeM