Hello,

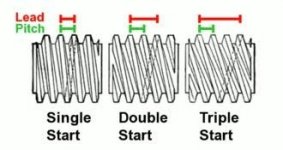

I was wondering if somebody could help clear this up for me. I'm looking to purchase some ACME thread gages. Our prints do not state if it is single-lead or double-lead, but I am noticing a lot of gages I see are stated as double lead.

I assume our shop is going to make the parts single-lead since there is not a specific callout. Can I mix single lead parts with a double lead gage? Or vice versa?

The parts have become a standard product for us and we recently found our early run shop gages had worn beyond use. The volume of the product line has increased and makes purchasing gages a worthwhile expense, especially considering we sell these as spare parts.

Thank you

I was wondering if somebody could help clear this up for me. I'm looking to purchase some ACME thread gages. Our prints do not state if it is single-lead or double-lead, but I am noticing a lot of gages I see are stated as double lead.

I assume our shop is going to make the parts single-lead since there is not a specific callout. Can I mix single lead parts with a double lead gage? Or vice versa?

The parts have become a standard product for us and we recently found our early run shop gages had worn beyond use. The volume of the product line has increased and makes purchasing gages a worthwhile expense, especially considering we sell these as spare parts.

Thank you