Airplane Guy

Aluminum

- Joined

- Feb 8, 2010

- Location

- Newton, KS

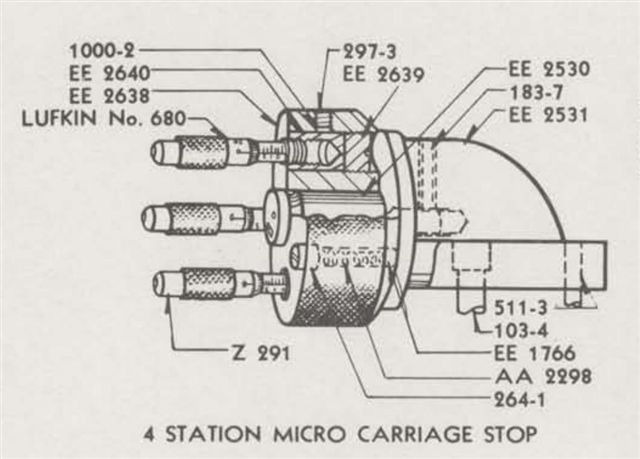

In an earlier thread I detailed a recent move picking up a 10EE. One of the attachments it has is a 4 Station Micro Carriage Stop. After looking through earlier threads here it looks like it probably isn't one of the more common attachments although I did find pictures of a few in much better condition than mine. Another member here offered to purchase mine and although I haven't decided to sell yet I wanted to at least clean it up to see what I have. This first photo is a close up of what it looked like on the machine. As you can see, this lathe has been neglected for many years but it's been inside and covered with a greasy muck which protected it pretty well.

In order to get it clean I decided to disassemble it completely. It's pretty amazing how many parts it took Monarch to do a proper job on their stop. They certainly didn't cut many corners back in the day.

It does look much better after getting rid of years of crud but it looks like it was probably never removed after delivery. It's taken some abuse over the years with some dings here and there.

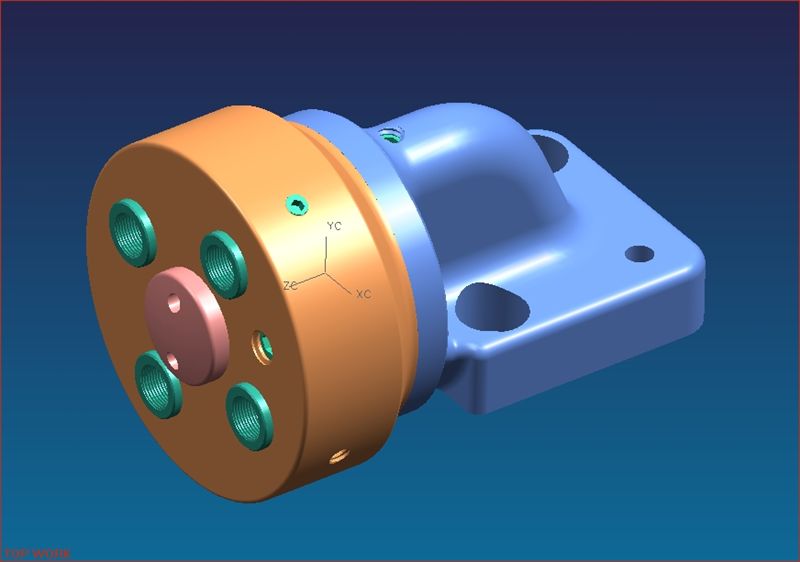

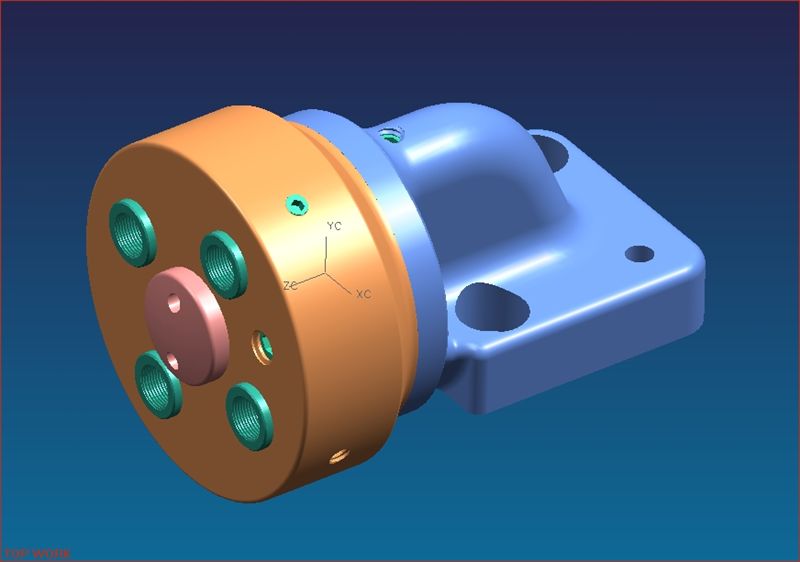

One of the things I wanted to do if I decide to take him up on his offer is make up some drawings in case I ever decide I need one of these some time in the future. There is nothing real complicated about any of the parts other than the base casting depending on how you're equipped. It could make a fun winter project. I started a model this weekend and I can make up drawings when I'm finished with it if anyone's interested. Let me know.

In order to get it clean I decided to disassemble it completely. It's pretty amazing how many parts it took Monarch to do a proper job on their stop. They certainly didn't cut many corners back in the day.

It does look much better after getting rid of years of crud but it looks like it was probably never removed after delivery. It's taken some abuse over the years with some dings here and there.

One of the things I wanted to do if I decide to take him up on his offer is make up some drawings in case I ever decide I need one of these some time in the future. There is nothing real complicated about any of the parts other than the base casting depending on how you're equipped. It could make a fun winter project. I started a model this weekend and I can make up drawings when I'm finished with it if anyone's interested. Let me know.