gernoff

Hot Rolled

- Joined

- Mar 19, 2011

- Location

- Great Falls, Montana

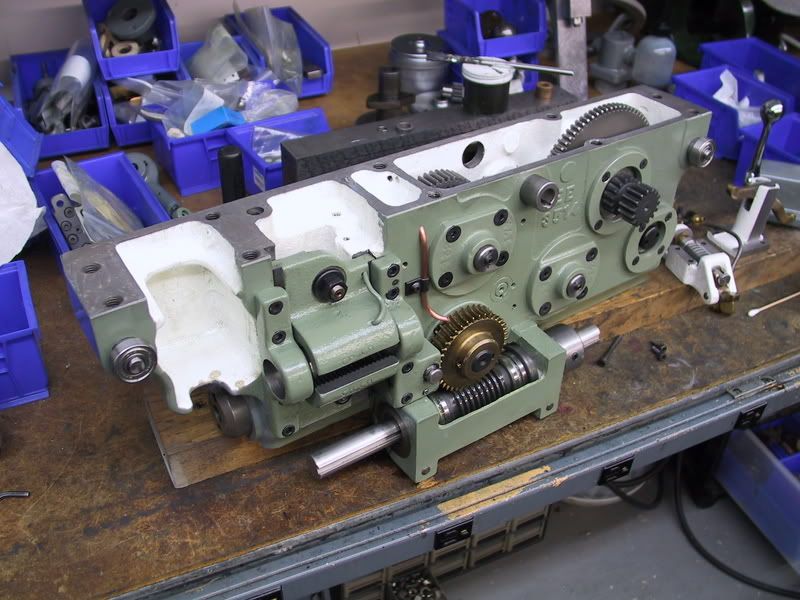

Bit of a photo essay of the teardown of my Monarch 10EE Apron:

Started on the backside with covers and the half nuts. The gib bearings are shown in the 4th picture, they are retained with spring rings. I used a drift punch and a good whack and the shaft pushed into the bearing and the ring came right off.

Started on the backside with covers and the half nuts. The gib bearings are shown in the 4th picture, they are retained with spring rings. I used a drift punch and a good whack and the shaft pushed into the bearing and the ring came right off.