I took some better photo's today.

Cal it looks like you do have some type of hole, just much lower in your first photo. Do you know what that's for?

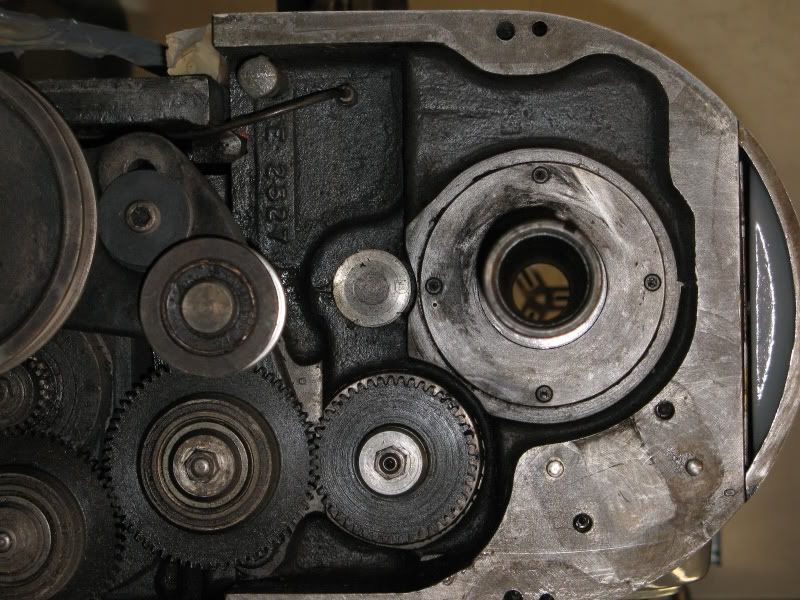

Here's a better shot top down, the casting is different compared to yours.

I have these numbers cast into mine, outside: EE 2527

And this on the inside:

I have a small maybe 1.5" by 2.5" access panel on the back of the head stock. I took it off and there was the rear bearing reservoir. Here's a close up. You can see the hole in the back of the cavity:

I made a white line at the same level as the sight glass level, you can see it on the right side of the machined edge of the casting. It's about even with the hole on the left side...

The hole has no threads, so I can assume there is not a threaded plug to go in there. One thing I thought about today, my tail stock end is pointed towards my garage door, thus the lathe is not level. I wonder if any oil would leak out of that hole if the lathe were level?

The other think I can do is plug the hole with a well nut?

I'm going to get a more precision measurement of the hole location relative to the top of the headstock and compare that with the oil sight glass level line. My guess is that the hole is an over flow, and the slope of my garage floor is causing the oil to flow out.

Ryan