Dear All,

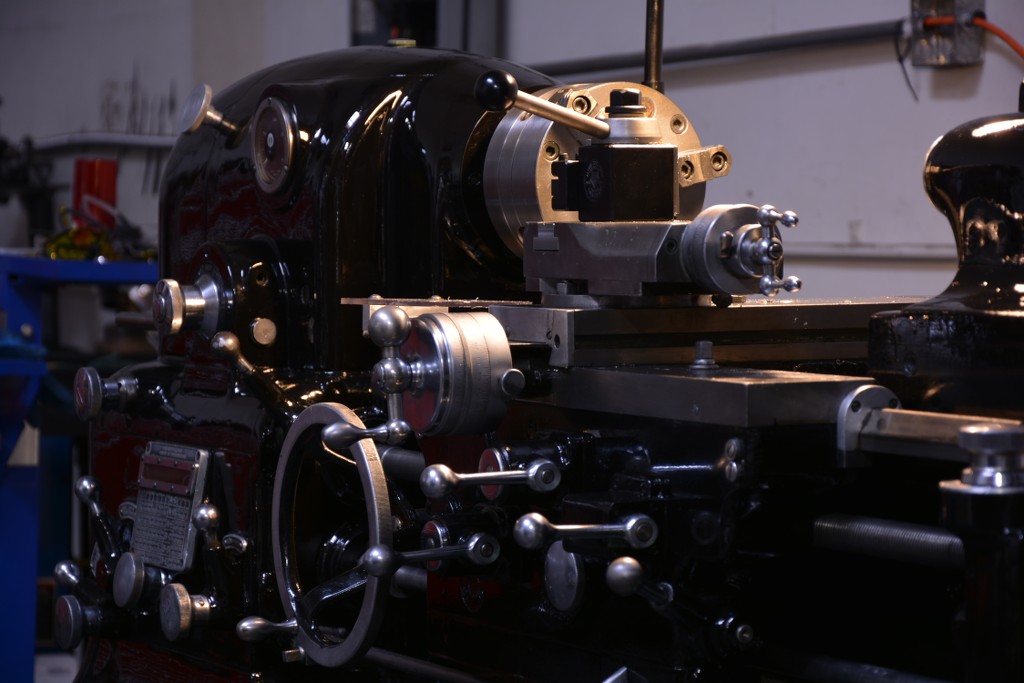

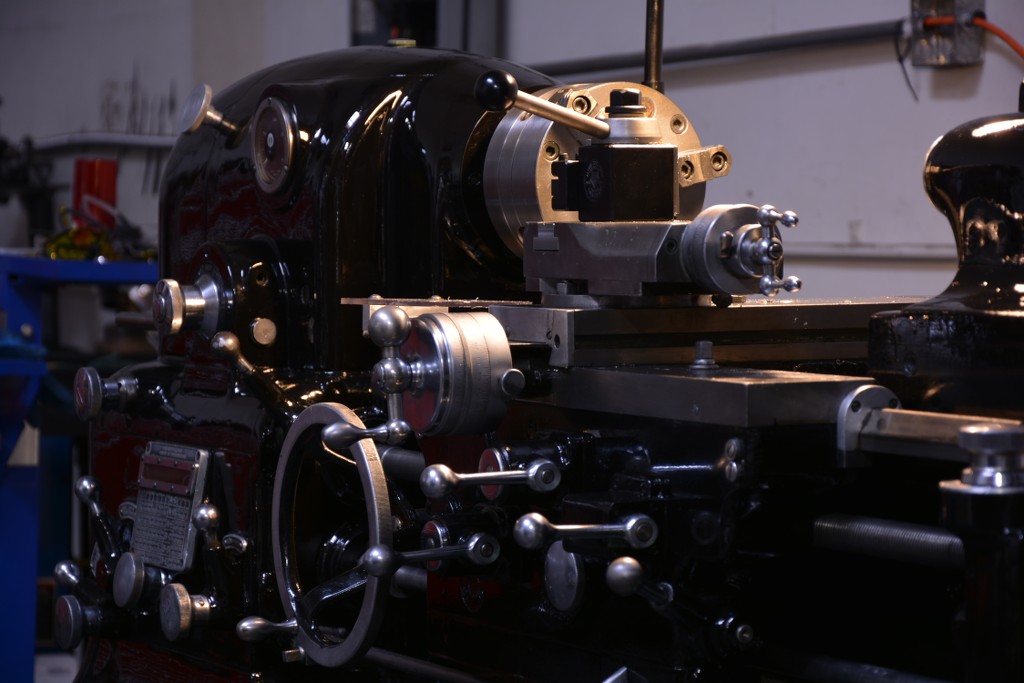

I think I need to start this thread with a picture of my girlfriend:

She has been my one and only for about 3 years now. Before the 10EE was a Grizzly lathe so you have an idea of how much I love my 10EE. My 10EE is pretty special. She's a 1968 with original modular drive. She went down a few times but everytime I was able to revive her with some simple maintenance and repairs. Pretty amazing that she is 50 years old this year and all original.

However, I'm considering purchasing another lathe. Besides the obviously size limitations with the 10EE (mostly length), I have a hard time drilling with it. The modular drive is cool and fancy but sometimes I wish it has good old gears and could let me drill a 1" drill bit through material at below 100rpm. The modular drive has limitations. It's not happy below 300rpm and I frequently struggle with it. In fact, anything larger than a 5/8" drill bit becomes quite troublesome.

The only thing I miss on the Grizzly was how it would happily hold 72rpm all day long. Although the entire machine was rattling and making funny sounds, I made a big hole.

Having been spoiled by the 10EE, I'm scared to get another lathe and be disappointed. I looked around locally and found the following interesting lathes:

1. Okuma LS

2. Monarch 610

3. Mori Seiki MS

They are all asking around the same price of $10k. It's scary how much the price of these machines have gone up. Anyways, could you all point me the right direction and if I'm making a good decision with these machines? If not, I'm completely open to your suggestions.

Thank you all so much for your infinite wisdoms.

Howi

I think I need to start this thread with a picture of my girlfriend:

She has been my one and only for about 3 years now. Before the 10EE was a Grizzly lathe so you have an idea of how much I love my 10EE. My 10EE is pretty special. She's a 1968 with original modular drive. She went down a few times but everytime I was able to revive her with some simple maintenance and repairs. Pretty amazing that she is 50 years old this year and all original.

However, I'm considering purchasing another lathe. Besides the obviously size limitations with the 10EE (mostly length), I have a hard time drilling with it. The modular drive is cool and fancy but sometimes I wish it has good old gears and could let me drill a 1" drill bit through material at below 100rpm. The modular drive has limitations. It's not happy below 300rpm and I frequently struggle with it. In fact, anything larger than a 5/8" drill bit becomes quite troublesome.

The only thing I miss on the Grizzly was how it would happily hold 72rpm all day long. Although the entire machine was rattling and making funny sounds, I made a big hole.

Having been spoiled by the 10EE, I'm scared to get another lathe and be disappointed. I looked around locally and found the following interesting lathes:

1. Okuma LS

2. Monarch 610

3. Mori Seiki MS

They are all asking around the same price of $10k. It's scary how much the price of these machines have gone up. Anyways, could you all point me the right direction and if I'm making a good decision with these machines? If not, I'm completely open to your suggestions.

Thank you all so much for your infinite wisdoms.

Howi