While taking apart the headstock on my 1942 EE10 to replace a broken clutch fork, I pulled off the "Regular Leadscrew Reverse Shifter" unit to clean out 70+ years of grit.

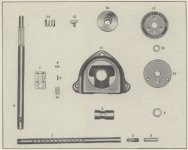

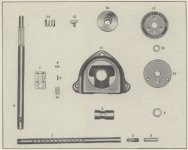

Looking at the parts catalog, I find I am missing parts, namely items 1, 2 and 3 and shown here.

Which has me asking, what do they do? Part #1 is call a "Stop Rod". It appears that as the carriage move to the left, it will press on the stop rod. Is the intent that it shifts the leadscrew into neutral?

Looking at the parts catalog, I find I am missing parts, namely items 1, 2 and 3 and shown here.

Which has me asking, what do they do? Part #1 is call a "Stop Rod". It appears that as the carriage move to the left, it will press on the stop rod. Is the intent that it shifts the leadscrew into neutral?

Attachments

Last edited by a moderator: