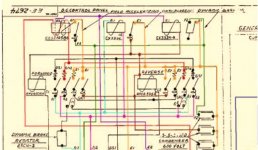

I’ve finally gotten the 10EE powered up and spinning via VFD. Everything works great except the forward rotation. Reverse works perfectly. I inspected the drum switch, cleaned it, and tried switching terminals. Switch checks out. Following the schematics on my machine it lead me to the Struthers-Dunn RPXA595A contactors for forward and reverse. One contact point looks pretty cooked. It seems replacements don’t exist anymore. I wouldn’t mind switching these to gain forward and lose reverse, until a solution could be made. Is there an easy way to address this before I pull everything out of the box??

Any advice would be appreciated.

Any advice would be appreciated.