I’m almost done reassembling my now refurbished apron (including mostly new gears, thanks nateman). Some questions:

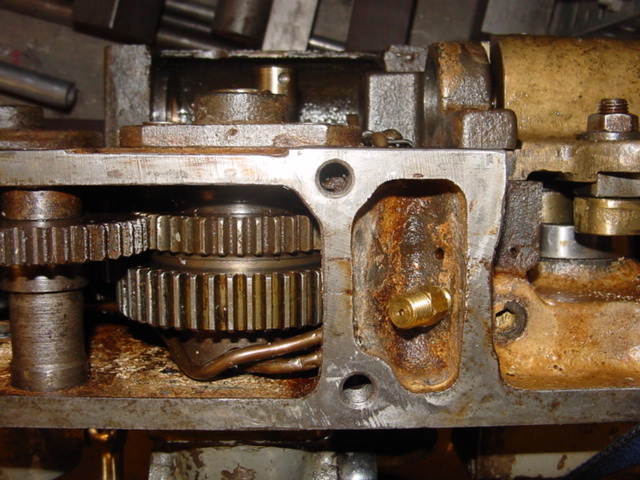

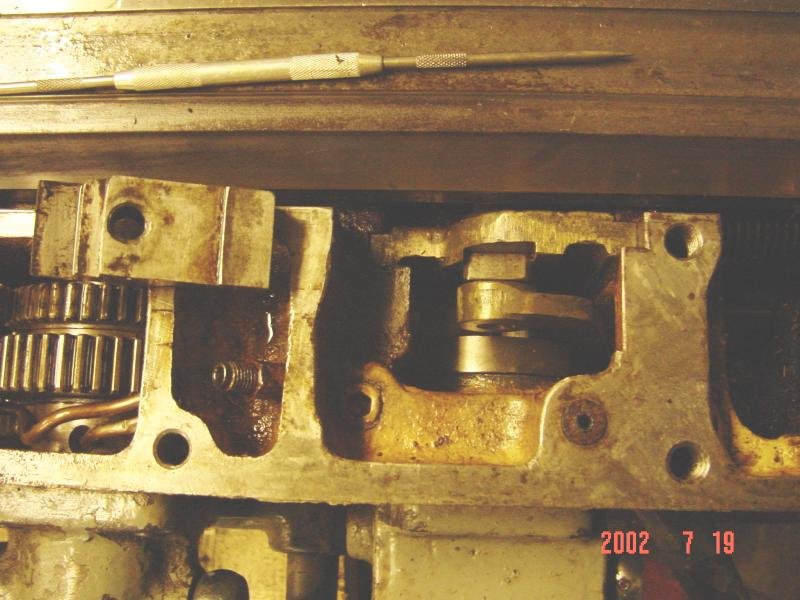

1. I don’t understand what is going on in the smaller base casting (see picture). It does get fed with oil from the bijur pump through the larger hole, but it looks like it will just pool in there and do nothing before dripping out. Is this only used for ELSR or something? Should I put a plug into the oil outlet hole? It is threaded. I don’t think the casting had a gasket when I took it apart, and monarch didn’t send me one when I asked for all the gaskets for the apron.

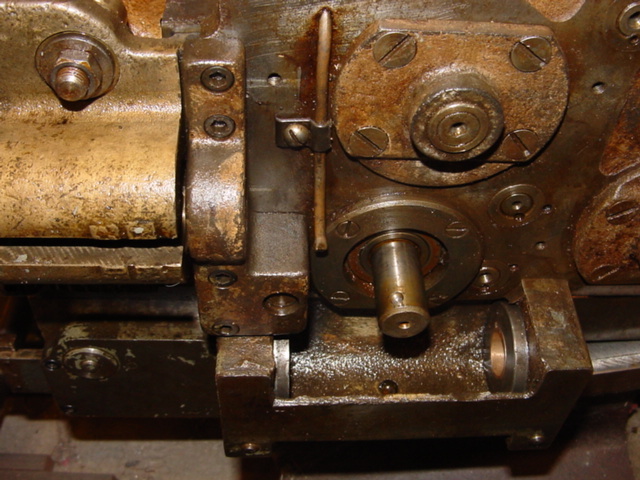

2. There are two oil lines at the top of the apron that look like they drip oil onto the gears. I basically destroyed the originals when disassembling. What should these be oiling?

Sent from my iPhone using Tapatalk

1. I don’t understand what is going on in the smaller base casting (see picture). It does get fed with oil from the bijur pump through the larger hole, but it looks like it will just pool in there and do nothing before dripping out. Is this only used for ELSR or something? Should I put a plug into the oil outlet hole? It is threaded. I don’t think the casting had a gasket when I took it apart, and monarch didn’t send me one when I asked for all the gaskets for the apron.

2. There are two oil lines at the top of the apron that look like they drip oil onto the gears. I basically destroyed the originals when disassembling. What should these be oiling?

Sent from my iPhone using Tapatalk