beckley23

Titanium

- Joined

- Feb 19, 2003

- Location

- Louisville, KY, USA

In a prior posting, linked below, Tom was inquiring about the volume of oil supplied by the headstock pump.

http://www.practicalmachinist.com/vb/monarch-lathes/12ck-headstock-oil-pump-volume-291622/

Since the pump is cam operated off the bull gear, the volume will change with changes in the bull gear RPM. Notice I said bull gear RPM, not spindle RPM. The bull gear is the same RPM as the spindle when the bull gear is used in the eight lower speeds, but it is not used in the eight higher speeds, but it is still turning, but at a much lower speed, approx 1/7th, of the spindle speed, at least from the calculation I did for shaft C when the shifters were set for the highest speed. For my lathe the bull gear is turning approx 196 RPM, when the spindle is turning 1400 RPM.

I noticed the difference when I investigated this situation in the linked post, but the only way to actually find out what the RPM was to count gear teeth. You can tell I've got a lot to do.

I've taken some pictures and made up a couple charts to illustrate.

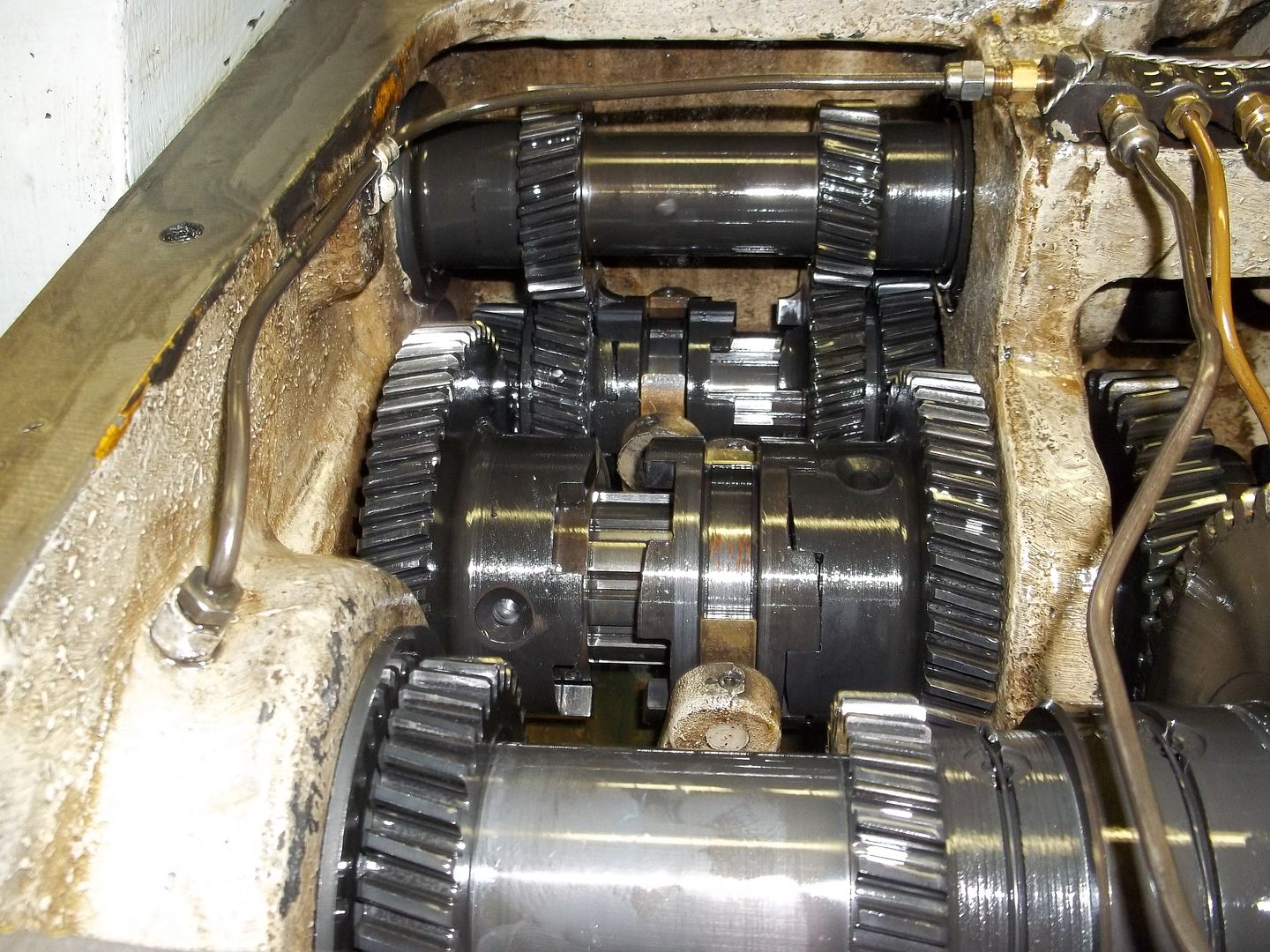

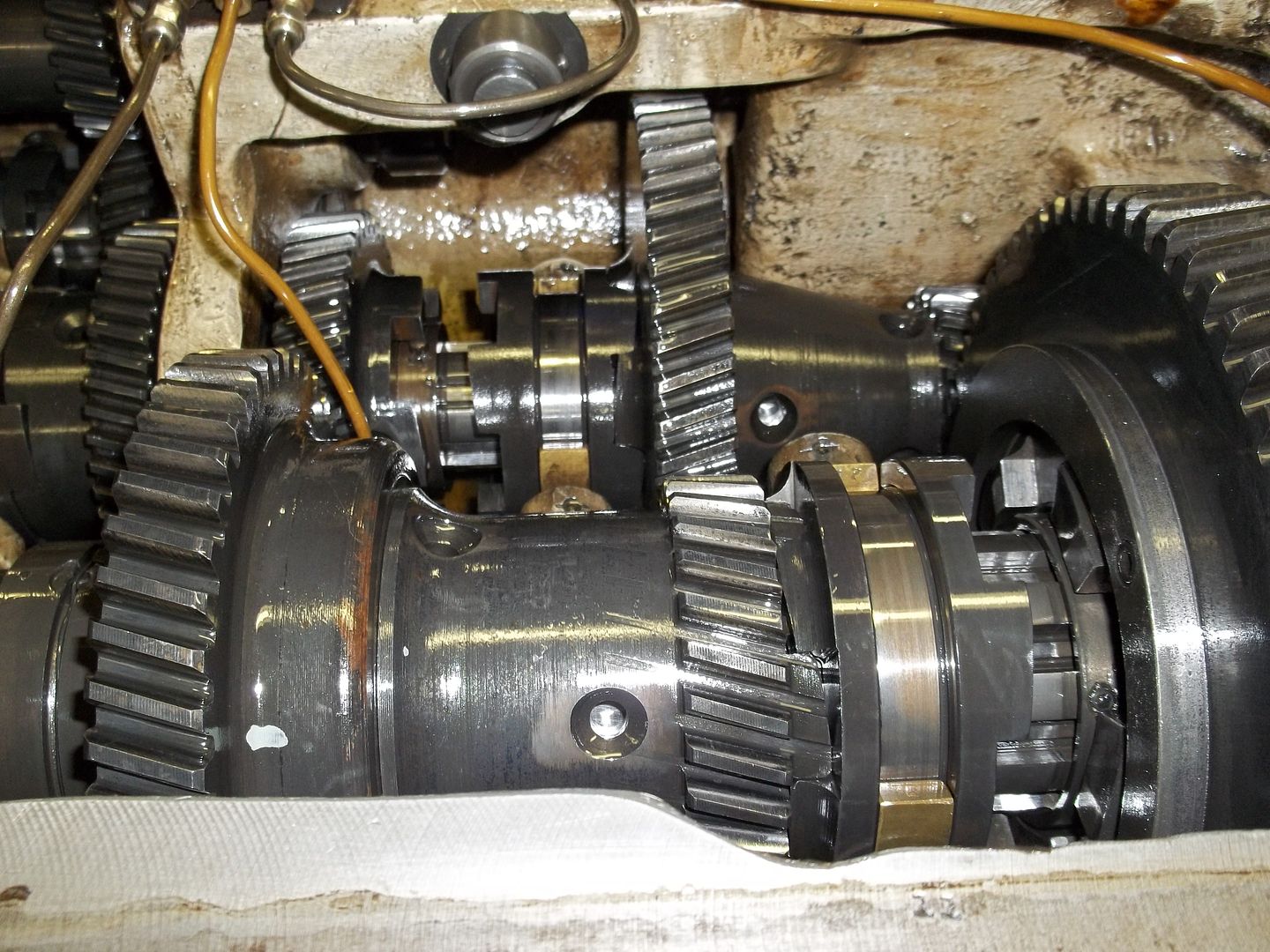

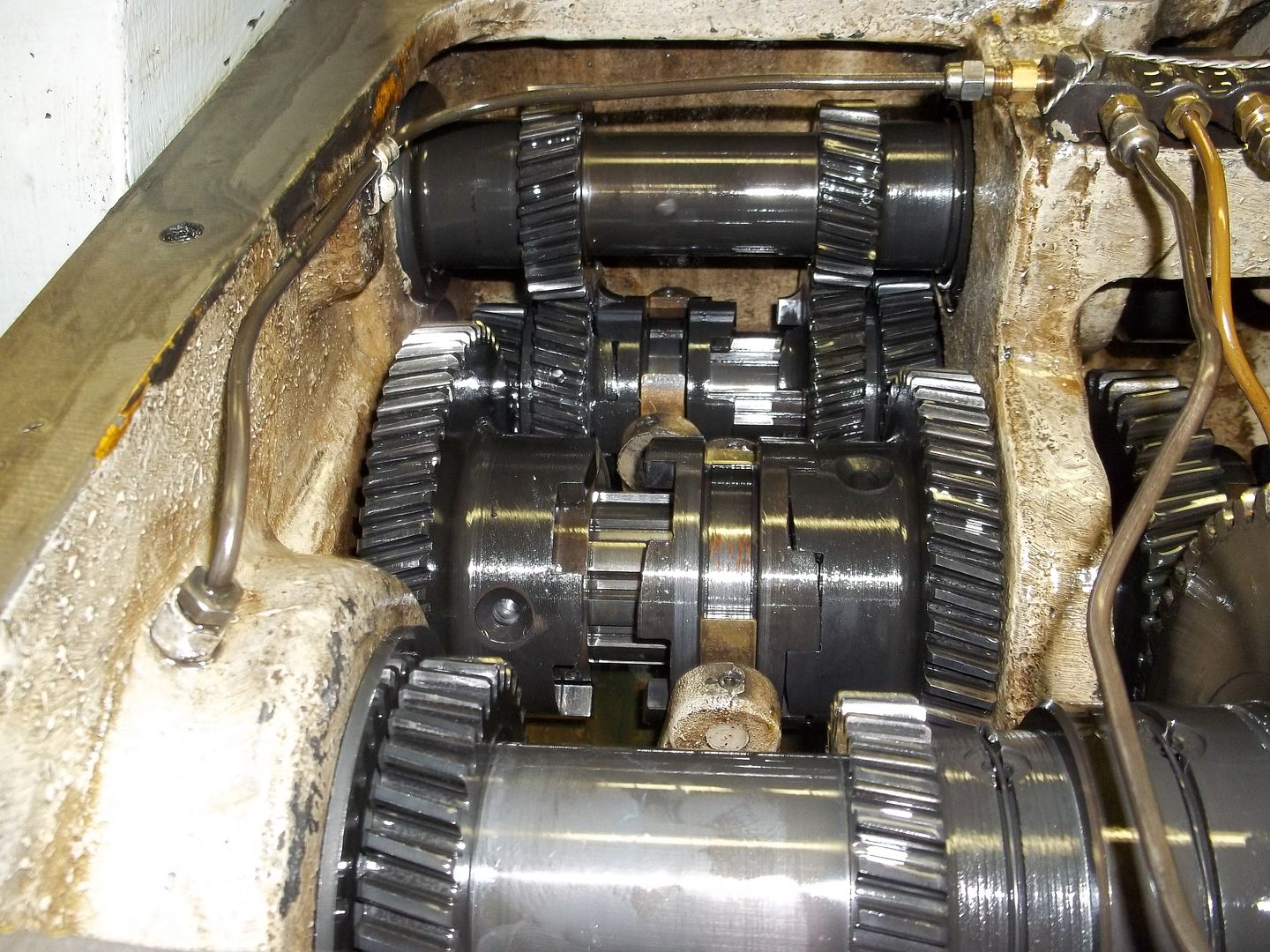

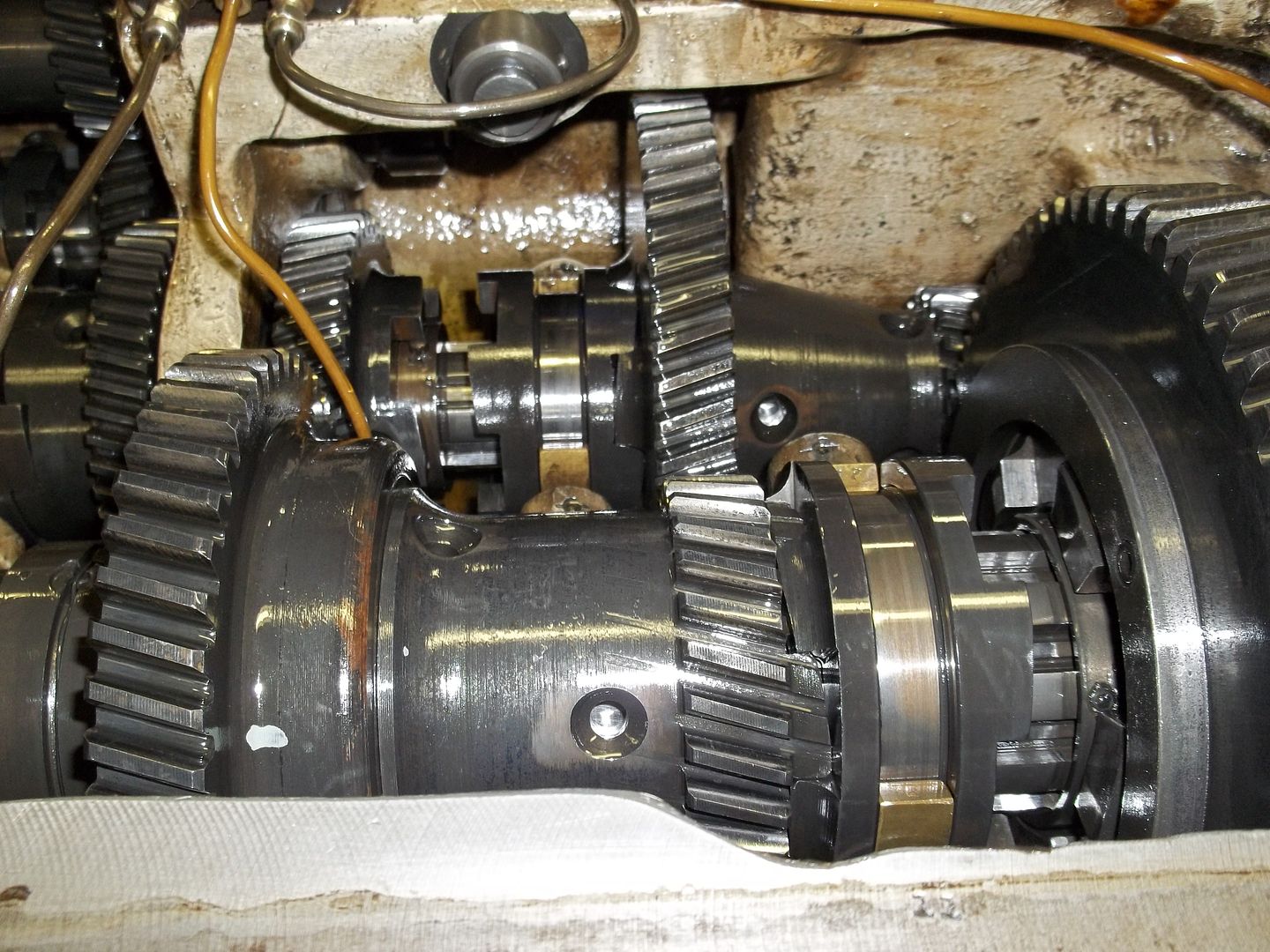

The first 4 pictures are of the headstock; the first are the shifters set for the highest speed, the second is an overall view of the HS internals, the third is of the left clutchs, the fourth is of the right hand clutchs. The three left shifters move the clutches in the same dorection as the shifters, the right hand lever moves the clutch in the opposite direction.

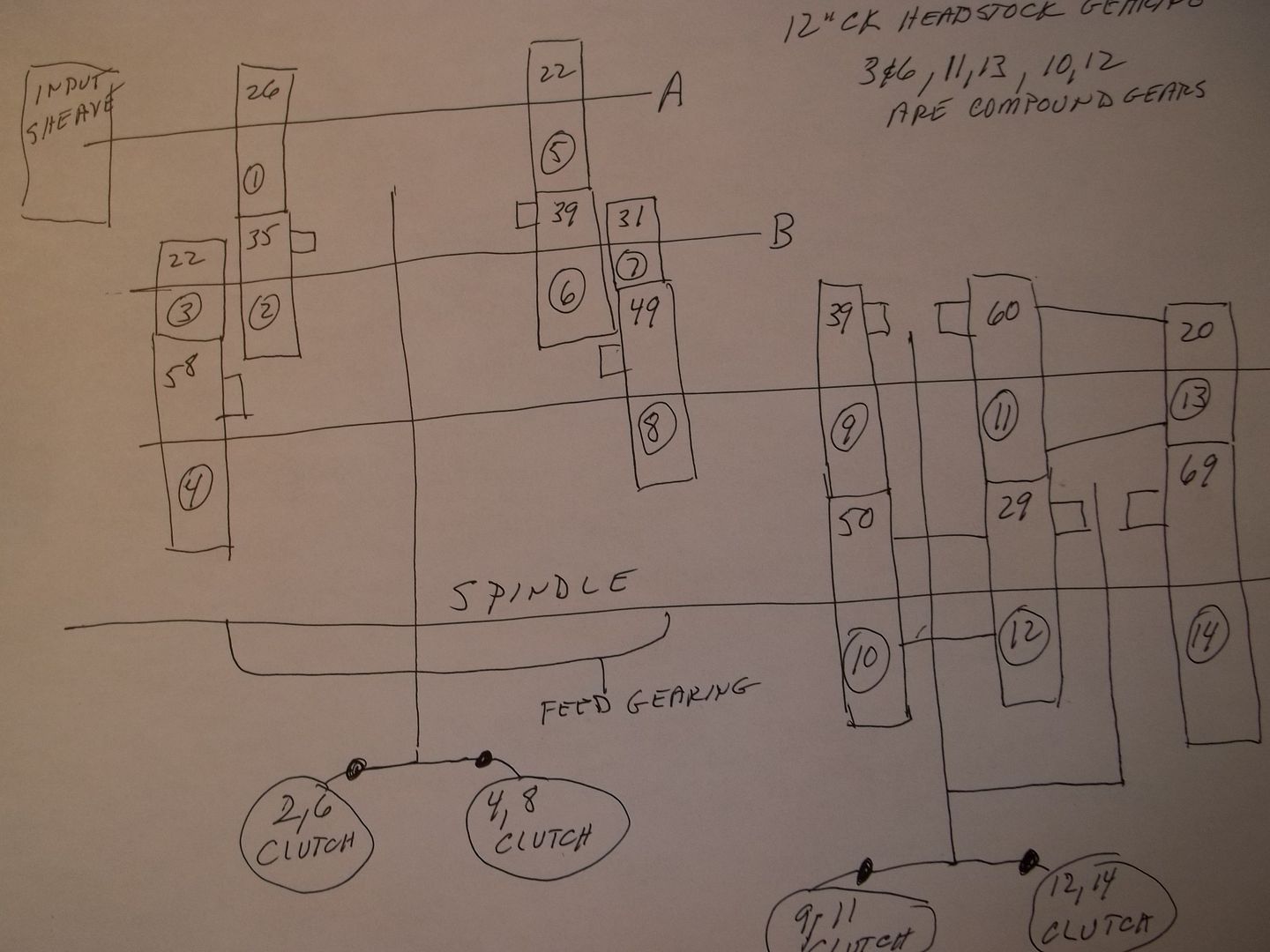

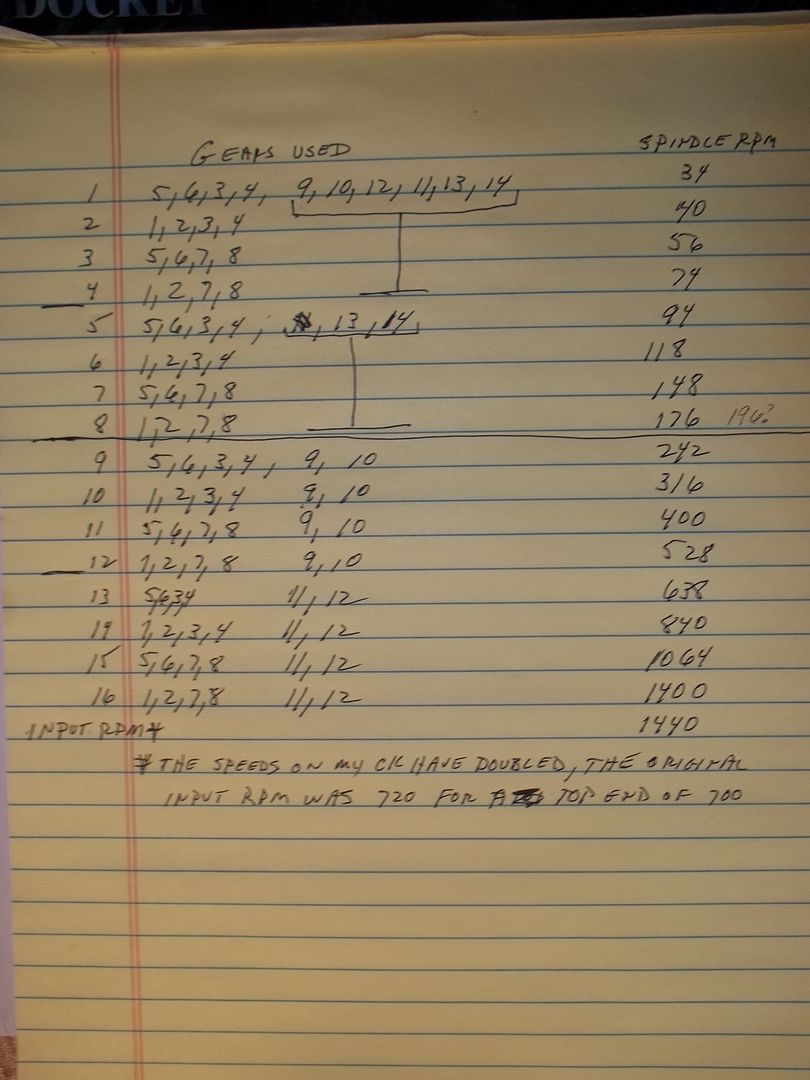

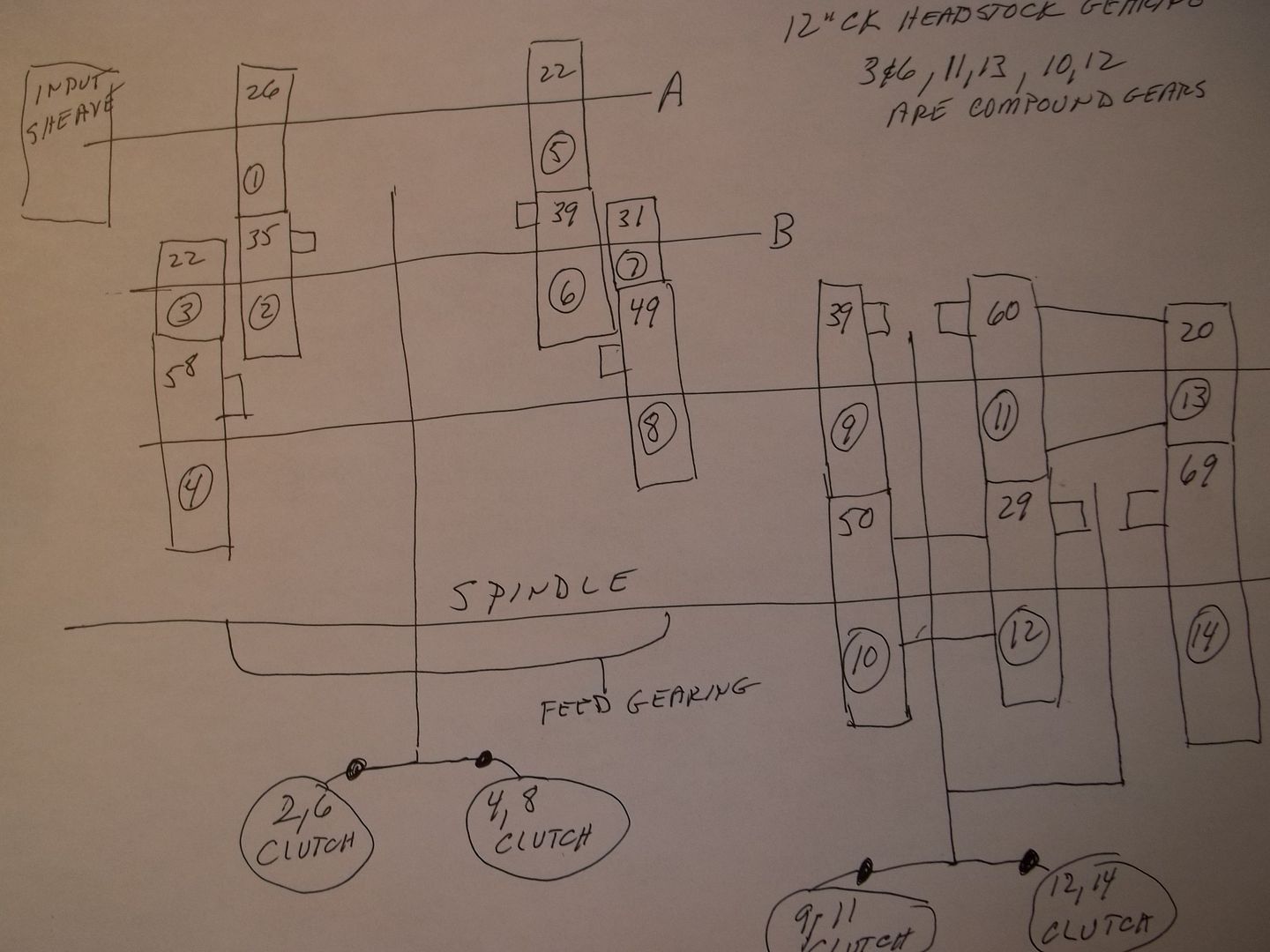

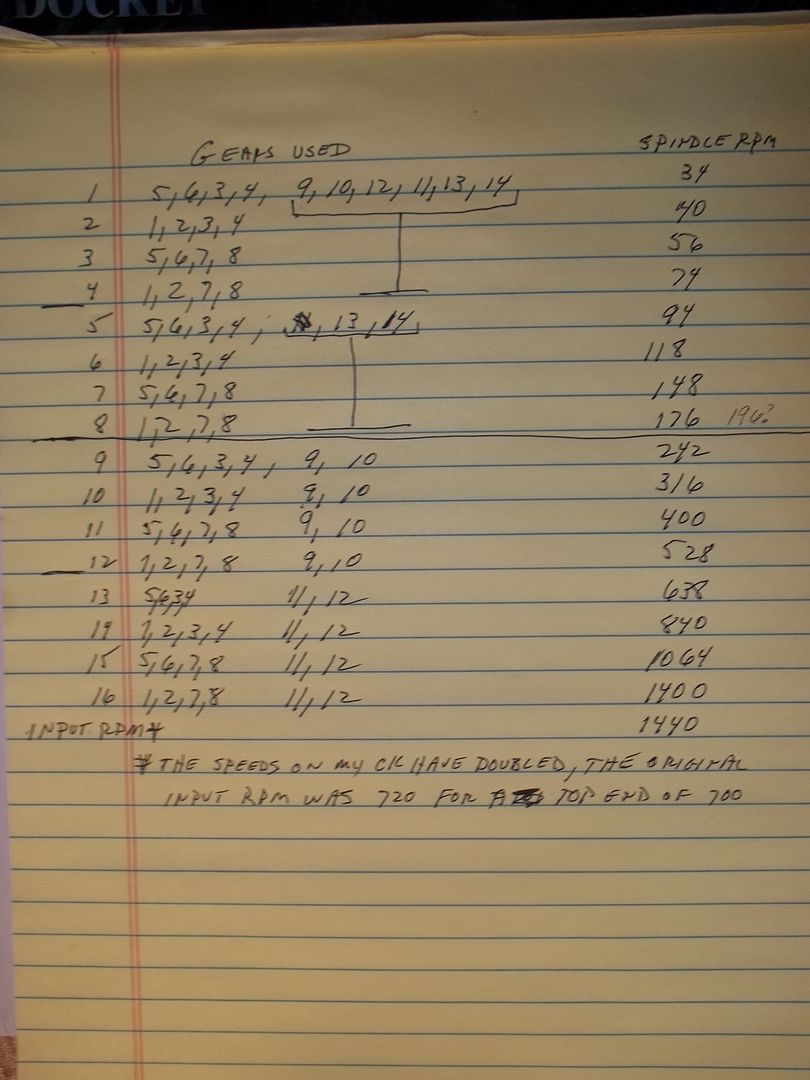

The fifth picture is a sketch or the HS gearing with tooth counts. The gears are identified by circled numbers 1-14. The last picture is a chart of the gears used in each speed. If you do the gear calculations, multiply the result by the input RPM, in my case that speed is 1440 RPM.

Oh yes, this still doesn't tell the volume of oil being pumped, just the number of strokes per minute of the pump.

One omission; I cut off the C & D shaft identifiers when I took the picture, sorry about that.

Harry

http://www.practicalmachinist.com/vb/monarch-lathes/12ck-headstock-oil-pump-volume-291622/

Since the pump is cam operated off the bull gear, the volume will change with changes in the bull gear RPM. Notice I said bull gear RPM, not spindle RPM. The bull gear is the same RPM as the spindle when the bull gear is used in the eight lower speeds, but it is not used in the eight higher speeds, but it is still turning, but at a much lower speed, approx 1/7th, of the spindle speed, at least from the calculation I did for shaft C when the shifters were set for the highest speed. For my lathe the bull gear is turning approx 196 RPM, when the spindle is turning 1400 RPM.

I noticed the difference when I investigated this situation in the linked post, but the only way to actually find out what the RPM was to count gear teeth. You can tell I've got a lot to do.

I've taken some pictures and made up a couple charts to illustrate.

The first 4 pictures are of the headstock; the first are the shifters set for the highest speed, the second is an overall view of the HS internals, the third is of the left clutchs, the fourth is of the right hand clutchs. The three left shifters move the clutches in the same dorection as the shifters, the right hand lever moves the clutch in the opposite direction.

The fifth picture is a sketch or the HS gearing with tooth counts. The gears are identified by circled numbers 1-14. The last picture is a chart of the gears used in each speed. If you do the gear calculations, multiply the result by the input RPM, in my case that speed is 1440 RPM.

Oh yes, this still doesn't tell the volume of oil being pumped, just the number of strokes per minute of the pump.

One omission; I cut off the C & D shaft identifiers when I took the picture, sorry about that.

Harry