Too many years ago now to dig records, but ISTR you were MY source for a used shifter fork I bought to replace the one on my '42 as was both BENT and thence badly worn?

Alfoden? That's how it works, here.

Each of us end up with the odd spare we turn out to NOT need.

Given we know how scarce they all can be, we just provide "safe-haven" from the scrap metal scavengers until some OTHER Pilgrim arrives who DOES need it.

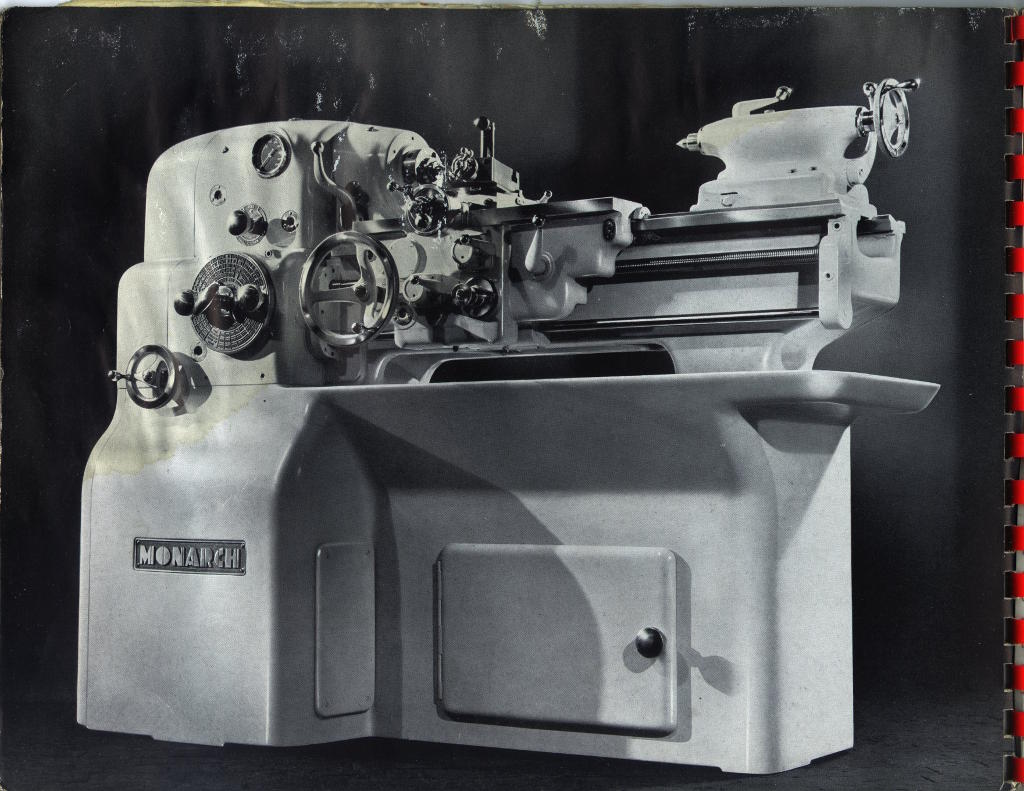

My own "safe haven" includes an entire spare 10EE, total of four motors for two lathes, plus about a 2 foot by six foot tower of loose parts just a few weeks ago finally coalesced into a former "Pier One Imports" castered steel retail display rack the liquidators were selling-off nearby. A twin to that rack now has a full set of alloys, new Conti's already mounted, for the vintage Jaguar up off the floor. Turns out the concrete under my debris field was still there, all along!

Go figure!

Other members have more parts stashed, yet!

A spare motor you have? That's a golden way to start!