Will McRay

Aluminum

- Joined

- Dec 31, 2017

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

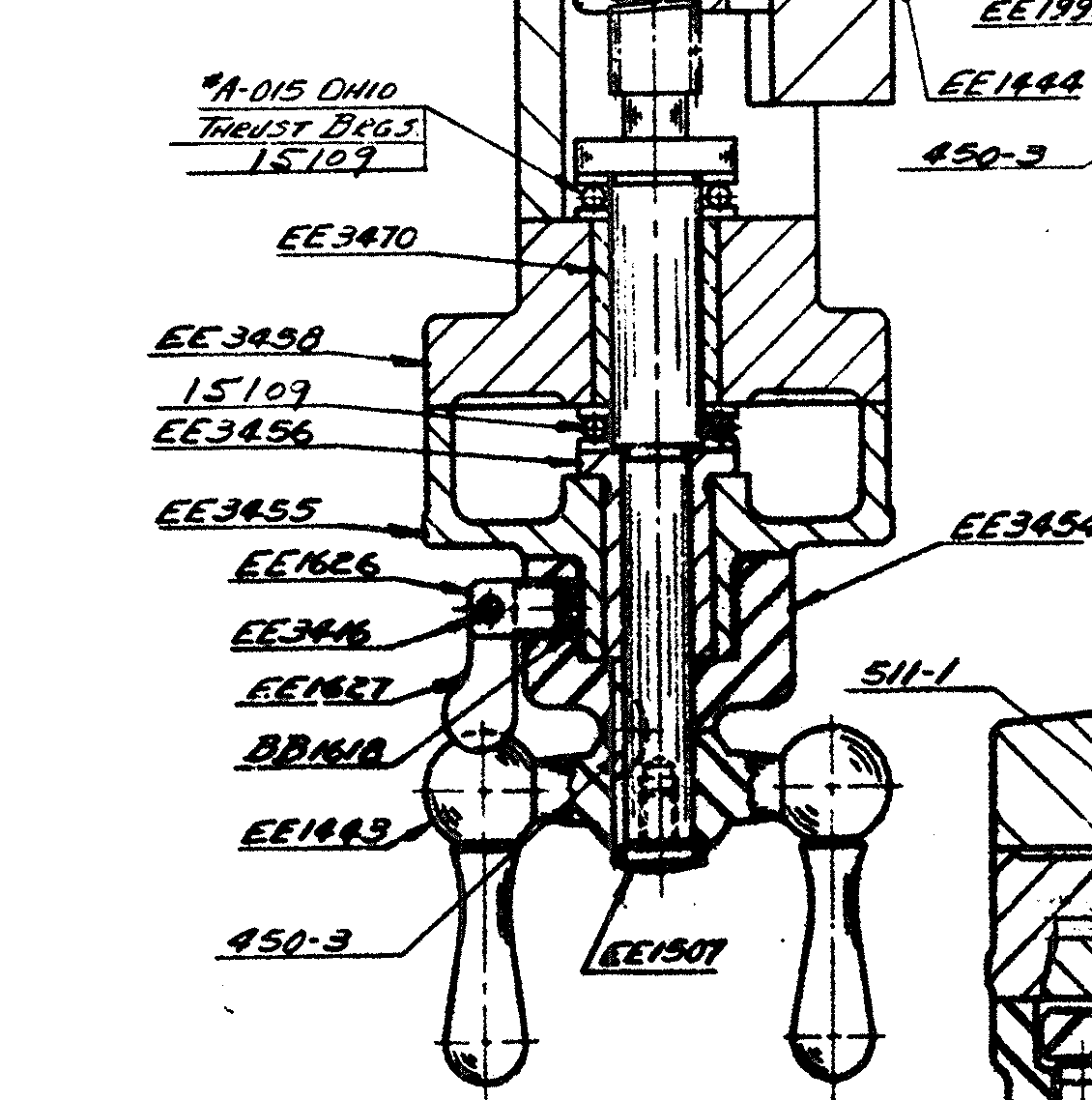

If I recall correctly, the handle is held on it's shaft with a plated screw with two holes in the head to use to tighten/loosen the screw. The handle has a small woodruff key providing a direct connection between the hands and shaft..

I seem to remember that if the handle retention screw is not fully seated, the handle and the first dial are free to move on the shaft.

I'd remove the handle retention screw and see if there is a problem like a burr on the woodruff key, or some other obstruction keeping the handle and dial from moving forward and properly controlling the endplay of the shaft.

DualValve

Roller thrust bearing? The ones that I've seen use ball-type thrust bearings.

Is the backlash the same all along the screw?

Does the gap in front of the dial change?

Cal

Take a look at the handle retention screw: if the handle is NOT pushed all the way onto the shaft, then there WiLL be endplay and a gap in the dial.

If the original Moarch screw is not around, find a proper threaded bolt or screw, put a suitable washer under the head, and thread it on.. The end of the shaft is roughly flush with the outer edge of the bore through the handle's center.

This screw in the middle of the shaft and it's job of pushing the handle as far in on the shaft as pose is the method in this design of having zero end play..

DualValve

Notice

This website or its third-party tools process personal data (e.g. browsing data or IP addresses) and use cookies or other identifiers, which are necessary for its functioning and required to achieve the purposes illustrated in the cookie policy. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise.