Maxim

Stainless

- Joined

- Apr 29, 2005

- Location

- Colorful Colorado

I'm looking at buying a Monarch 10ee with a DGSC rebuild tag from the summer of 1993

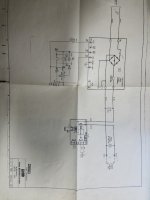

It has a fincor drive on it (origionally a MG machine I believe). The seller doesn't have it under power since

it needs 440V to run as is.

I believe the bed has been reground.

I think there are a few owners here with this rebuild and I was wondering what they think of it.

Monarch doesn't have a record of any parts being bought for this machine at all.

Its a bit of a drive but price seems reasonable and I think the drive can be made to run on 2ph 220 with a slight reduction in performance.

It has a fincor drive on it (origionally a MG machine I believe). The seller doesn't have it under power since

it needs 440V to run as is.

I believe the bed has been reground.

I think there are a few owners here with this rebuild and I was wondering what they think of it.

Monarch doesn't have a record of any parts being bought for this machine at all.

Its a bit of a drive but price seems reasonable and I think the drive can be made to run on 2ph 220 with a slight reduction in performance.