Bordaco

Plastic

- Joined

- Sep 24, 2007

- Location

- Bolivia - Cochabamba

Hi, I know this is for lathes, but I have a Monarch VMC150 whit a DC300 spindle drive, and sundendly come in error (afther working two years whit out problems) whit error code LED :

000100 FL04 FlOSS loss of field current (L,T)

Acording to monarch thec support is:

- CFU1, 2 or 3 on Power supply card blown

- 1PL disconnected or damaged

- Field grounded

- Field lead connections

- Open field circuit

- FLDLS set to high

- FC gain jumper set wrong

- Field regulator gain too low- adjust BFLPG

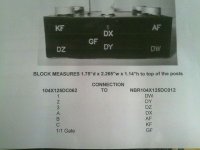

We dont have manuals for this drive, and I think is the diode powerpak (Gentron Powertherm 104X125DC12ST), The digital tester tell me that is bad, but i not shure, because I don't have a power diode test equipment.

Any coments?, sugestions, experience similar problems?.

All is welcomed.

Regards.

Boris, From Bolivia South America

PD, there is no GE service here

000100 FL04 FlOSS loss of field current (L,T)

Acording to monarch thec support is:

- CFU1, 2 or 3 on Power supply card blown

- 1PL disconnected or damaged

- Field grounded

- Field lead connections

- Open field circuit

- FLDLS set to high

- FC gain jumper set wrong

- Field regulator gain too low- adjust BFLPG

We dont have manuals for this drive, and I think is the diode powerpak (Gentron Powertherm 104X125DC12ST), The digital tester tell me that is bad, but i not shure, because I don't have a power diode test equipment.

Any coments?, sugestions, experience similar problems?.

All is welcomed.

Regards.

Boris, From Bolivia South America

PD, there is no GE service here