Glock34

Plastic

- Joined

- Jul 30, 2019

- Location

- Connecticut, 'Merica

Hey All,

I picked up a 10EE a couple of weeks back, and I have a few questions.

Here's what I know about this particular unit.

It is a round dial, M-G machine, MFGR'S # is 25476, build date: 7-1944.

It has ELSR, (most of) a taper attachment, and an Accumulating Cross Feed Dial.

I purchased it from a manufacturing company that used it in their tool room. I was told that it was removed from service because it would surge, but otherwise worked fine. It was wired to 480v 3ph.

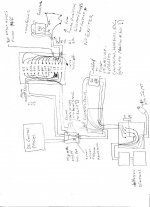

I have already learned a ton of stuff reading through many threads here, but as is my luck, this unit has a couple of modifications that are baffling, as well as a potentially dangerous modification. I will attach a couple of drawings of the wiring I've traced out so far that will show the mods I need help with.

First, the dangerous mod. The AC contactor, heaters, etc. have been completely bypassed by a push button on/off switch. Questions: Is this contactor assembly available in it's original form, with a 220v coil? Is there a suitable replacement available that would fit under the cover? Could the overload heaters/switch just be replaced by circuit breakers?

Next is the input power. This was plugged in to 480 3ph, but that was run directly to two, (single phase), transformers, and the wiring on those is, for lack of a better word, goofy. (See attachment.) Has anybody ever seen transformers wired like that? I do have to say that I Googled that model transformer, but could not find an internal diagram for it, so internals on my drawing are based on my experience with transformers. It could be wrong, but even if it is, well, just look at the wiring!

Last, (for now). There is NO EXCITER! It has been replaced with a 440-115 transformer, a big ol' resistor, & a fuse! I have been unable to find this type of mod anywhere. Has anyone seen/done this? Is this a workable mod?

Possibly the biggest problem I have is that I cannot test the machine due to no 480v 3ph power, and need to sort this stuff out so I can decide what the best way to go would be. Should I trash the whole electrical system & go with a single phase 220v motor? Assuming I could convert to 220v, build a phase converter? Go with a VFD? Convert the motor to single phase via the Steelman method, (again if possible, no extra wires from the M-G windings)? Any other suggestions?

Thanks in advance!

Ted

I picked up a 10EE a couple of weeks back, and I have a few questions.

Here's what I know about this particular unit.

It is a round dial, M-G machine, MFGR'S # is 25476, build date: 7-1944.

It has ELSR, (most of) a taper attachment, and an Accumulating Cross Feed Dial.

I purchased it from a manufacturing company that used it in their tool room. I was told that it was removed from service because it would surge, but otherwise worked fine. It was wired to 480v 3ph.

I have already learned a ton of stuff reading through many threads here, but as is my luck, this unit has a couple of modifications that are baffling, as well as a potentially dangerous modification. I will attach a couple of drawings of the wiring I've traced out so far that will show the mods I need help with.

First, the dangerous mod. The AC contactor, heaters, etc. have been completely bypassed by a push button on/off switch. Questions: Is this contactor assembly available in it's original form, with a 220v coil? Is there a suitable replacement available that would fit under the cover? Could the overload heaters/switch just be replaced by circuit breakers?

Next is the input power. This was plugged in to 480 3ph, but that was run directly to two, (single phase), transformers, and the wiring on those is, for lack of a better word, goofy. (See attachment.) Has anybody ever seen transformers wired like that? I do have to say that I Googled that model transformer, but could not find an internal diagram for it, so internals on my drawing are based on my experience with transformers. It could be wrong, but even if it is, well, just look at the wiring!

Last, (for now). There is NO EXCITER! It has been replaced with a 440-115 transformer, a big ol' resistor, & a fuse! I have been unable to find this type of mod anywhere. Has anyone seen/done this? Is this a workable mod?

Possibly the biggest problem I have is that I cannot test the machine due to no 480v 3ph power, and need to sort this stuff out so I can decide what the best way to go would be. Should I trash the whole electrical system & go with a single phase 220v motor? Assuming I could convert to 220v, build a phase converter? Go with a VFD? Convert the motor to single phase via the Steelman method, (again if possible, no extra wires from the M-G windings)? Any other suggestions?

Thanks in advance!

Ted